February 24, 2023 | Author: André Nimtz | Reading time: approx. 8 minutes

The challenge: maximum flexibility in the process industry

What "batch size 1" is for discrete manufacturing, for the process industry it is the most flexible and efficient implementation of individual customer requirements. Small batches, short delivery times, high variance and shortest times to market are the requirements of the hour. The key to this lies in modular production: relatively rigid plants designed for long-term operation are increasingly becoming modular plants whose modules - called Process Equipment Assembly (PEA) in technical terminology - can be exchanged and reassembled as required depending on the production goods - locally or even across sites.

But one major problem remains: the flexible, in the best case automated control of the modular plants. If all the modules speak different languages, the engineers still have plenty of work to do reading out the data and linking it in the process orchestration layer (POL) to form a functional overall picture. A uniform interface standard is intended to remedy this situation: the Module Type Package (MTP).

The solution: Module Type Package (MTP) as a unifying standard

What exactly does Module Type Package mean? MTP is a non-proprietary interface standard that enables manufacturers to store the complete functional description of a PEA on the plant module itself. This includes the description of the data objects, the visualization and further information, for example on alarms.

In real life, this means that you simply plug the new module into your existing plant and read out the data of the Module Type Package in your Process Orchestration Layer. The MTP operates like a driver for the new module. For your engineers, there is no need for time-consuming plant engineering, because the new modules are seamlessly integrated into the existing plant without much effort. This is why the industry also refers to this approach as "plug-and-produce".

Glossary

MTP (Module Type Package)

XML file in Automation Markup Language (AML) format, which is stored on the plant module by the manufacturer and describes all features as well as the visualization of the module in the POL.

PEA (Process Equipment Assembly)

Plant module that fulfills a specific function, e.g. a pump or a separator. Individual PEAs can be linked to form plants of any complexity.

POL (Process Orchestration Layer)

Control layer of the plant in which the MTPs are read, interpreted, linked and visualized.

Plug-and-Produce

describes the approach that MTP-capable modules only need to be "plugged in" to an existing system or "plugged together" to form a new system, and production can then begin without any further effort. At the very least, MTP saves time-consuming engineering, but true plug-and-produce only becomes possible with full automation.

IIoT platform

a suite of industrial functions, usually provided as software-as-a-service, that can be used for data acquisition, automation, connectivity, data analysis, predictive maintenance, etc. In the best case, it replaces all isolated solutions of a company and interacts with higher-level systems such as ERP or MES.

The advantages of Module Type Package (MTP) for plant operators

Module Type Package brings enormous potential - for module manufacturers, for system integrators and above all for you as a plant operator. We present some of the advantages to you.

Advantage #1

one-time module engineering, reusable modules

Instead of explaining to each plant part with each new order what its function is and via which interface it has to communicate, the module engineering is done initially by the manufacturer. Interfaces and logic of the process are defined once and a visualization is specified. All this is written into the Module Type Package. The module thus has its defined functions and limits. It can be used quickly and flexibly at any time.

Advantage #2

lower costs thanks to Module Type Package

With MTP you save engineering costs. Thanks to plug-and-produce, it is no longer necessary to adapt new modules to the process. You buy exactly the module you need for your production from the module manufacturer, including the predefined Module Type Package. Engineering times and costs for plant engineering, i.e. setting up the actual plant, are also noticeably reduced. It only takes a few clicks to connect the MTP.

Advantage #3

MTP noticeably increases your flexibility

Multi-product and multi-purpose plants benefit greatly from modularization. Since Module Type Package eliminates programming efforts at the module and interface and new plants can be set up in the Process Orchestration Layer in no time at all, plant operators are able to convert their plants quickly and even at short notice. Almost any process line can be implemented in a very short time. MTP makes it possible to react particularly flexibly to market requirements.

Stay up to date – subscribe to our newsletter now

We regularly deliver news about our products and solutions directly to your inbox. Get exciting insights into customer projects and stay on the cutting edge of IoT news and trends. Simply sign up for our free newsletter.

Practical example: Module Type Package meets IIoT platform – MTP taken a step further

The Module Type Package is an important driver of modular production and also the starting point for automation in the process industry. However, the importance of the Process Orchestration Layer must not be neglected. It is just as important as a unified module language, because it processes the flow of information, provides the human-machine interface and performs essential functions such as recipe control. In practice, individual solutions can be found just as much as prefabricated platforms for process control.

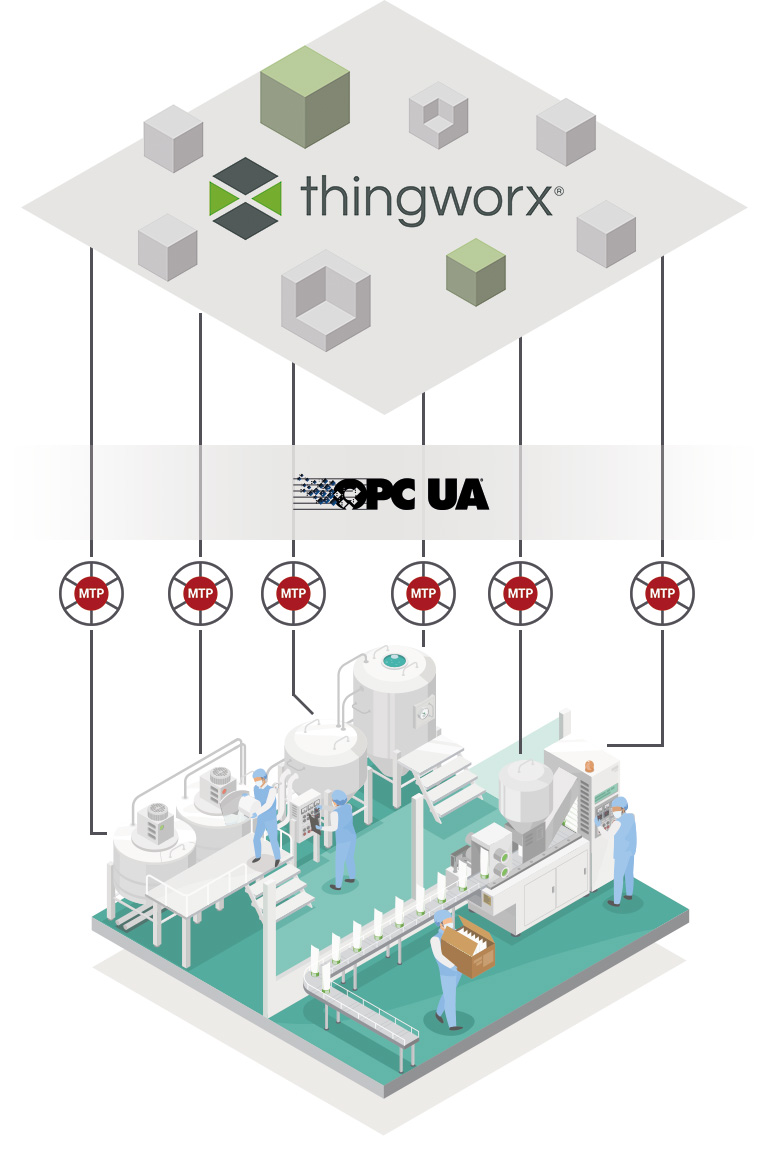

Another option is found in IIoT platforms such as ThingWorx, which bring several advantages at once:

- You expand your POL with a platform that can be used for more than just the production process.

- You can implement more advanced evaluation and management functions within the platform.

- You achieve a higher degree of automation.

We have already implemented this scenario in a pilot project for and with our customer Evonik. ThingWorx is in use at Evonik as a DataHub, which has been expanded to include the functionalities of a POL, and is establishing itself as a decentralized automation platform. This opens up numerous possibilities for process optimization and automation:

- automation of the import of Module Type Packages into the system and also their deletion

- automated connection establishment via OPC UA

- establishment of a communication link between the modules

- comprehensive visualization or control over the visualizations of different MTPs

- …

The ThingWorx-POL solution can interpret MTPs from different manufacturers and provides the user with a uniform process orchestration layer that is open for numerous further use cases. Read more about this ThingWorx-based solution by following this link.

Conclusion

The Module Type Package is a fundamental building block for modern manufacturing companies in industries such as chemicals, pharmaceuticals or food processing. Individual modules or PEAs, which can be combined quickly and flexibly to form complex plants, form the basis for tomorrow's competitiveness. If these PEAs also speak the same language, namely MTP, then the set-up and management of entire plants can be accomplished with significantly less cost and time expenditure. It gets especially exciting when process control is in the hands of an IIoT platform like ThingWorx. This opens up additional possibilities for you in terms of automation, process orchestration and also the evaluation of data.

Orchestrate and automate processes with ThingWorx POL

Meet the growing demands of the market: with ThingWorx POL you can achieve the flexibility and efficiency you need for a process industry 4.0.

Interview with Sebastian Härtner: MTP in the real world

What is the status quo of MTP and what are the requirements? We talked about this with Dr. Sebastian Härtner from Merck.