Essential features for all industries

With weasl, you have all the features you need for paperless manufacturing and thus for digitalizing your work processes. Create work instructions and integrate all necessary information and media. Define process sequences according to the qualifications of your workers. Benefit from digital verification and process documentation. This and much more is enabled by our flexible worker guidance system.

Work paperless and increase efficiency

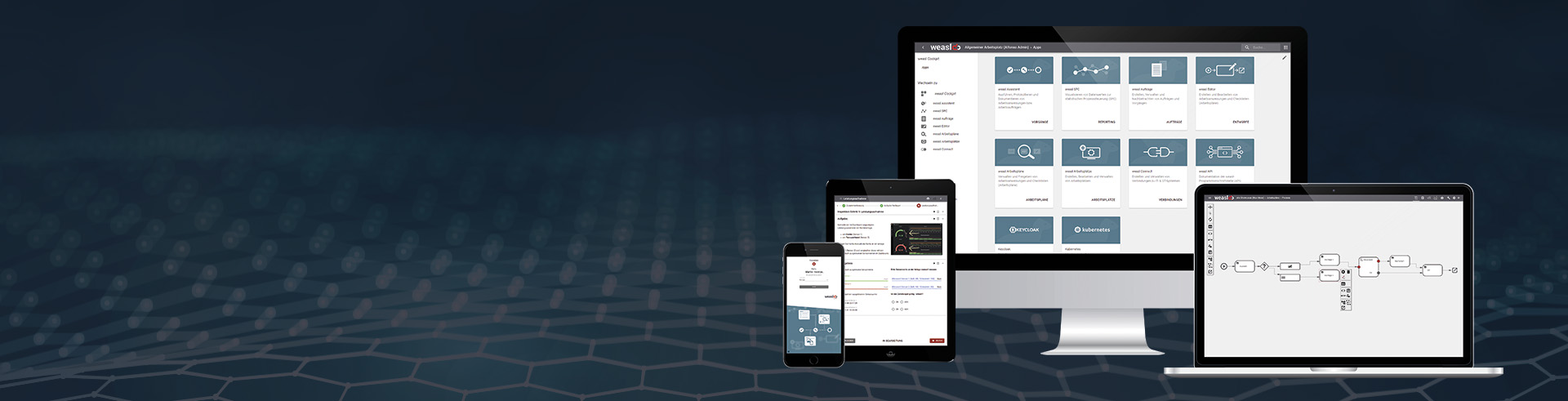

Drag-and-drop editor for work instructions, work plans and checklists

With the weasl editor you can create, edit and manage work plans, work instructions and checklists independently and easily.

Following the modular principle, you can compile "step-by-step" work instructions for your employees and enrich each work step with explanatory texts, images, videos and much more, as well as equip input forms with configurable validation functions.

Tip: Use the predefined templates or import existing work plans from your IT systems.

![]()

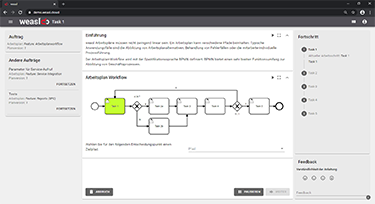

Integrate diverse media types into work instructions

Increase your productivity with meaningful work instructions. Depending on the qualification of the workers, a work plan can be reproduced with varying levels of detailed assembly support.

In addition, you can display or have texts read aloud in the work instructions, integrate images and videos, or interactively view 3D models from your CAD system. Most common file formats are supported.

Tip: It is also possible to display Excel tables or to integrate existing instructions as PDF documents.

Step by step to more product quality with weasl

![]()

Reliable execution of work plans and checklists

weasl guides the worker safely and efficiently through order execution. The individual work instructions are specified and explained in accordance with defined work plans. The level of detail can be adapted to the qualification of the worker. Digital process documentation is also provided for each task.

Parallel processing and switching between work orders is possible at any time.

Tip: Integrated dashboards for available work plans and open work orders facilitate the overview.

![]()

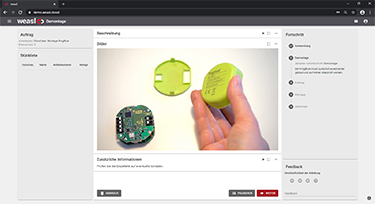

Verification and digital quality control chart

With "weasl Reporting", you can enter required quality parameters during the execution of work plans either manually (by input) or automatically (from peripheral systems) for verification. Entry forms can perform validation, force alternative work instructions and also lock the process if required.

In addition, the module offers you the option of statistical process control. Monitor your manufacturing processes and ensure your product quality.

Maximum flexibility for convenient working

![]()

weasl supports many devices and is customizable

weasl can be used on both stationary and mobile devices. Thanks to configurable displays, work instructions and checklists can be optimally used on any device, regardless of whether you are working with a PC, smartphone, tablet or data glasses.

Tip: Company-specific interface designs can be configured just as easily with weasl as the independent addition of further languages. German and English are already included.

![]()

Reading in QR code & more

With weasl, you can easily scan a variety of 1D/2D codes and thus integrate and process product data or status information directly in your work plans during process execution.

Simply use the camera of the smartphone/tablet or a camera connected to the PC for scanning.

Tip: All common codes such as QR code, barcode or data matrix code are supported. The assignment of individual data from the code (GS1) to corresponding weasl forms is configurable.

Efficient and reliable paperless production with weasl

![]()

Easy integration into your IT and production environment

weasl has a modern, modular architecture. You can easily connect your existing IT systems via standard interfaces. This way, you can always access current order data and documents from your MES or ERP system from within the work plans.

Via a large number of existing connectors, weasl can integrate data from your machines, systems and production environment into the workflow and document it directly at the respective work step for digital verification.

![]()

User management

weasl uses the "OpenID Connect" standard (OIDC) for authentication and authorization of users. This allows you to easily integrate weasl into your existing user administration and simply use your existing user, role and rights structure.

Tip: If required, weasl also provides a separate user administration.

![]()

Security and data protection

Data exchange between the weasl end device and the backend always takes place securely via encrypted connections.

Passwords are never stored on the end device or transmitted to the backend.

Weasl processes data according to your specifications: You determine yourself which data, e.g. on a person, is used by weasl. Recorded test data is stored in archive tables without reference to a person.

weasl is operated as SaaS at a certified cloud provider (AWS).

Book your demo appointment

weasl revolutionizes your production and offers you all the tools you need for paperless manufacturing and the digitalization of your work processes. See for yourself and arrange a demo appointment right away.