The potential of IIoT applications for production and maintenance

Industrial IoT has numerous facets that contribute to increasing your production. The most essential ones include:

- visibility into your production based on metrics such as OEE or other KPIs.

- harmonization of these key figures across multiple production sites

- media-interruption-free recording and transfer of information

In the area of maintenance, too, predictive and tailored maintenance in particular leads to an increase in machine utilization and a reduction in downtimes. Benefit from Smart Services as the interface between machine operators and machine manufacturers.

Take advantage of the potential of our IIoT solutions. Together with you, we create direct added value for your individual use case.

Creating visibility

Creating transparency

Making predictions

IIoT applications: our offer at a glance

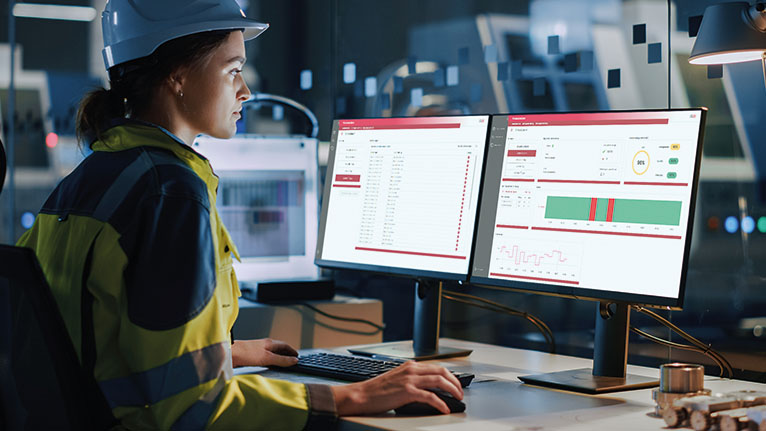

Customer & machine portals

Customer and machine portals offer machine builders and machine users many added values. They create the basis for condition monitoring of your machines and the possibility of remote diagnosis, right through to predictive maintenance. This allows maintenance intervals to be optimized, service calls to be planned efficiently and machine downtimes to be minimized.

Furthermore, our web solutions based on proven building blocks are the platform for additional digital services and new business models.

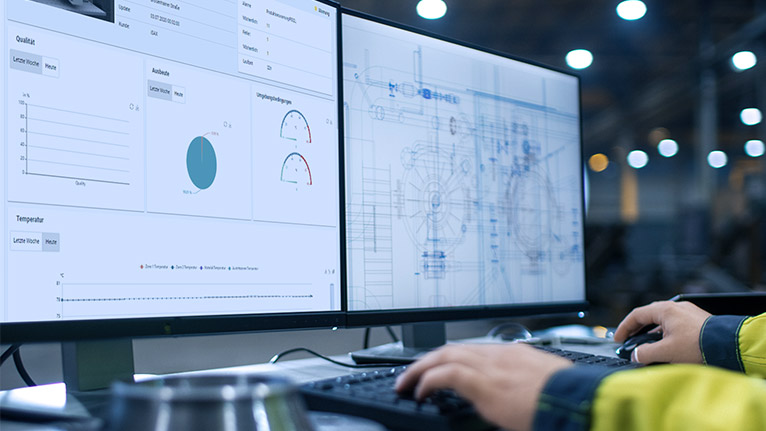

Dashboards

Dashboards visualize consolidated status data from production in a clear and easy-to-understand manner. Depending on their use, they support both the workers in production in the efficient execution of their work steps and the management in the control of higher-level production processes and in the detection of deviations.

Work with us to create improved transparency about your production or individual manufacturing steps on the basis of OEE and other key performance indicators.

Analyzing data

The continuous collection and processing of machine and production data offers the possibility to combine and analyze information in a targeted manner. Data-based solutions – often referred to in connection with Big Data, Data Analytics or Predictive Maintenance – enable companies to improve manufacturing and maintenance processes, quality control and quality assurance as well as optimized after sales.

Rely on our experience to identify further optimization potential in your company and use data profitably.

Individual IIoT applications

The individual challenges of Industry 4.0 are diverse and the requirements for Industrial IoT applications vary accordingly. We develop solutions that focus on the integration of your data and the optimization of your manufacturing processes. In doing so, we rely on established IoT platforms and thus solve even complex requirements efficiently and securely.

But even beyond that, we are your contact when it comes to individual implementations according to your specific needs - from the integration of a Kardex warehouse to the control of an industrial robot.

We work with these partners

We are happy to advise you

We offer expert, industry-experienced support from consulting to implementation. Talk to our experts and tell us what you want to achieve with your IoT application.

Continue reading

Optimize production with OEE dashboards

Predictive maintenance for high availability

ThingWorx - the platform for your IIoT applications