last updated: August 26, 2024 | authors: André Nimtz & Maren Fichtner | reading time: approx. 19 minutes

What is a worker guidance system?

Industry is characterized by manual work. Whether in the assembly of components or the maintenance of machines - people remain an integral part. It is therefore essential to provide them with the best possible support in their daily work. This is the task of a digital worker guidance system.

A worker guidance system helps your workers to carry out their work efficiently and without errors. At its core, such a system consists of software that shows the worker all the information they need about their work steps. At the same time, the system documents the entire process.

Software-only solutions offer clear added value compared to hardware-based pick-by-light systems (or pick-by-voice, pick-by-scan or pick-by-vision). Pure software is more flexible and can be used independently of the workstation, but can be connected to the desired hardware via appropriate interfaces.

Worker guidance system or connected worker platform?

In the specialized press, you often read of a technology that seems to be replacing worker guidance systems: the connected worker platform. However, it is not the name that determines which system is best suited to your company, but the variety of functions and flexibility. Modern worker guidance systems can certainly keep pace with connected worker platforms or even offer more advanced functions.

A digital worker guidance system is something like a worker's sparring partner. It provides support in precisely those areas where a worker's specific tasks lie. And it relieves them by making tasks easier or taking them off their hands completely. The tasks of a worker guidance system include

- guiding and supporting the worker, e.g. by providing step-by-step instructions

- the provision of information on their tasks, e.g. design drawings

- quality assurance of the work steps, e.g. through correction instructions or test steps

- (automatic) data acquisition, e.g. process data collection or shop floor data collection

- a reporting function, e.g. through the automatic creation of protocols

- the provision of communication tools, e.g. feedback functions

![]()

App for executing work instructions

At its core, a worker guidance system naturally offers an app to provide your workers with the latest work instructions and step-by-step instructions. Your workers should be able to use the system intuitively and on different end devices and have access to interactive functions such as data collection, confirmations and feedback options.

![]()

App for creating and managing work instructions

How do the work instructions get into the worker guidance system? In the most basic form, via an editor. This is where you create and design work instructions according to your specifications and requirements. The system should be usable without programming knowledge and offer a sufficient degree of flexibility.

![]()

Open interfaces

So that not everything has to be done manually, a worker guidance system should also have open interfaces for integration into existing systems for data exchange, e.g. with an ERP.

![]()

App for reviewing the completed work instructions

The third essential component of a worker guidance system should be an overview of all completed work orders. Evaluations and analyses based on the automatically documented entries and steps performed should be possible here.

![]()

High flexibility

Flexibility starts with openness. Good worker guidance systems are so open that they can be optimally integrated into your existing IT infrastructure and company processes - both in SaaS and on-premises operation.

When it comes to creating work instructions, good worker guidance systems do more than just map linear sequences. A modern system opens up a wide range of process modeling options. Of course, this starts with simple checklists, but extends to complex processes with dependencies and branches.

Advanced systems even perform in-process quality checks as dynamically integrated test steps, thus enabling a particularly high level of quality assurance in sensitive processes.

![]()

User-friendliness & interactivity

An advanced system does not display the same information and instructions to every employee, but is based on the qualification profile. By displaying only the necessary information, the system does not overload your employees with information and therefore reduces their mental workload.

A good system can also provide overarching information such as health and safety instructions for retrieval in the corresponding work instructions.

In addition, advanced worker guidance systems have advanced feedback functions that enable sustainable process optimization. For example, messages can be sent to different departments directly from the system or reasons for faults can be recorded directly. Really good systems even go so far as to integrate the basic functionality of a PDA system: The worker can record productive times during processing and correct working times if necessary.

![]()

Scalability & future viability

As your company grows, your worker guidance system should not fall by the wayside. Good systems grow with you and allow you to get started with just a few licenses or without explicit integrations, for example. When the time is ripe for more consistency, simply scale the existing system according to your requirements.

Scalability automatically means that the system is future-proof, especially if the worker guidance system is based on a modern architecture and modular expandability.

![]()

Adaptability to different requirements

A good worker guidance system not only has the worker in mind - but also the quality assurance engineer, the industrial foreman, the maintenance technician, etc. It can be used in a variety of ways in different areas of the company and therefore helps to eliminate isolated solutions.

As a result, the worker guidance system can establish itself as a standardized information platform for cross-departmental use. This in turn helps to democratize data in production-relevant areas of the company.

Pay particular attention to ensuring that the system can adapt to your processes and language and not the other way around. Good systems map the customer-specific specialist domain quickly and comprehensively with the help of process data.

The 4 most important reasons for using worker guidance systems

Modern, multi-variant production presents workers with special challenges. They have to carry out a wide variety of processes reliably and without errors. Each process requires different knowledge and requires the worker to constantly change over. The smaller the batch sizes, the more the human factor becomes a potential source of error. Worker guidance systems give you a clear competitive advantage here. Why? We have summarized four important reasons for you:

![]()

Effort reduction in work preparation

Before each order or even work step, the worker has to compile the required documents or correctly interpret printed CAD drawings and filter out the correct information for processing. This eats up time, impairs productivity and increases the risk of errors. With a worker guidance system, you can prevent all of this by always providing your workers with the information they need for each work step digitally.

![]()

Avoid errors during manual activities

A worker guidance system helps you to effectively avoid errors in assembly or other manufacturing processes by providing your employees with clear and unambiguous work instructions. It provides the required information for each work step, ensures the correct process sequence and integrates test steps into the process. This saves you time-consuming rework and additional costs for complaints.

![]()

Reducing documentation effort

In production, consistent documentation and, increasingly, verification obligations and the associated effort and costs are part of day-to-day business. Here, too, worker guidance systems provide support by automatically logging the activities of your workers digitally. Your employees enter test and measured values directly into the system and do not have to be laboriously transferred afterwards.

![]()

Significantly simplified training processes

Regardless of whether you want to train a new colleague or introduce a worker to a new process: The training phase takes time and also blocks the experienced employee who is doing the training. Support your workers with a worker guidance system and significantly reduce training times by providing detailed step-by-step instructions. This ensures a consistently high level of training and your workers are productive more quickly.

Beyond this, there are many other arguments in favor of using a worker guidance system in your manufacturing company:

- efficient design of complex and multi-variant assembly processes

- reduction in order throughput times

- immediate error detection and rectification

- noticeable relief for employees

- consistently high process reliability and quality in the production process

- one hundred percent transparency of the workpiece history

Assembly

A worker guidance system is predestined for assembly in production, as manual processes are part of the daily work here. A digital assistant provides your workers with clear work instructions and makes the necessary information available. Additional test steps at the work stage help to identify and avoid errors during assembly.

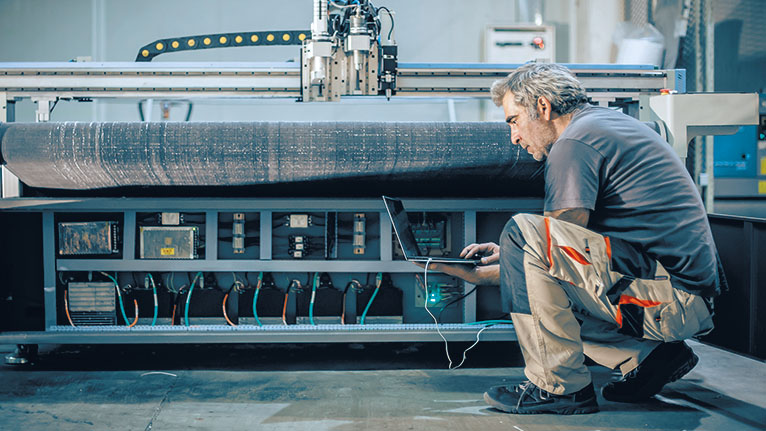

Maintenance

This is where flexible, workstation-independent worker guidance systems come into their own. The maintenance technician receives machine-specific work orders with all relevant information, e.g. on a tablet, and returns collected data digitally. Paper-based processes are eliminated and errors in work preparation and data transfer are reduced. This saves you valuable time.

Commissioning machines and systems

With a good worker guidance system, you can easily map commissioning processes. Provide your personnel with a standardized procedure that can be fully customized depending on the machine type. During the workflow, the system documents all steps and ensures consistent digital verification.

Quality assurance

A worker guidance system offers valuable approaches to quality assurance on several levels. The seamless integration of inspection steps within the work instruction enables immediate error detection and correction - the keyword here is worker self-inspection. The data recorded during processing provides detailed insights into input and measured values and, thanks to automatic documentation, a worker guidance system helps to fulfill verification obligations.

Training employees

Thanks to step-by-step instructions, a worker guidance system is predestined for training employees - either for new hires or when training them in new processes. Good systems adapt to the user's qualifications so that, ideally, no support from experienced colleagues is required. Experienced employees, in turn, can use a worker guidance system for knowlegde retention or knowledge transfer.

Alpha Verteilertechnik: worker guidance in control cabinet construction

With variants consisting of thousands of components and assemblies, the assembly of control cabinets is a real challenge for every worker at Alpha Verteilertechnik. Among other things, they must

- ensure the positioning of the correct component

- observe electrical and mechanical values

- and select the correct torque.

The worker has to compile all the information he needs to complete his job from drawings, bills of materials and paper files. Mixed-up or forgotten components and incorrectly assigned torques are not uncommon. With the introduction of our worker guidance system weasl, Alpha Verteilertechnik has tackled the most critical points and created significant relief for the workers. The worker guidance system:

- guides the worker step-by-step through the assembly process.

- automatically provides all information pre-selected and correctly assigned so that the worker can concentrate on the actual work.

- ensures the desired product quality and significantly reduces work preparation time.

SCHOTT: Glass processing with the help of a worker guidance system

For SCHOTT as a manufacturer of high-tech materials for specialty glass, the flawless execution of complex and demanding machining processes is essential to ensure consistently high product quality. This includes, among other things

- regular tests and measurements during the lengthy CNC machining process

- documentation of the tests on the machine terminal

With the introduction of our worker guidance system weasl, SCHOTT pursued the goal of eliminating Excel-based paper instructions and establishing direct feedback options for the workers. Thanks to the openness of the system and its high level of flexibility, SCHOTT has been able to leverage significant potential. These include

- the elimination of paper instructions

- the provision of all information for setting up the machine, including instructions via the system

- ensuring the high quality specifications

- automatic documentation of the recorded input values and therefore better traceability

- direct feedback of the processing order to leading systems

As with the introduction of any digitalization solution in your company, you should consider certain points that will lead you to the ideal worker guidance system. In this case, however, we would like to emphasize a second perspective that plays a special role in the acceptance of the system: Your workers. If you want to introduce a worker guidance system into your production, it is not only important to look at the solution, but also, to a particularly high degree, at worker acceptance.

A look at the solution finding process

![]()

Finding use cases and determining added value

Check what specific added value a worker guidance system would bring to your processes and look at the use cases in which such a system would be of direct benefit. If you want to think ahead, check in which directions you could scale the system.

![]()

Research

There are now numerous providers on the market. Have a look around, google and create a shortlist of potential systems.

![]()

Contact solution providers

Talk to solution providers and describe your specific goals. Compare the desired functionalities, price expectations, etc.

![]()

Test

Use test environments or demo access to get an idea of the systems. How does it feel to work with the worker guidance system? Do you find all the functions? Can you imagine working with the system?

![]()

Decision-making

Compare the systems again on the basis of the facts you have gathered and your practical experience. Does one system offer everything you need? Then the decision is made.

![]()

Introduction and continuation

Now it's time for the technical implementation in your production. Gather feedback from your employees and optimize your processes or the integration of the system.

A look at worker acceptance

![]()

Clearly formulate reasons and goals

Communicate openly about your plans. Increase acceptance among your employees by formulating clear statements about what you want to achieve and how your employees will benefit from it. This will enable you to identify supporters for your project at an early stage. You can direct personnel energies and bundle resources.

![]()

Getting employees on board

Involve your employees at an early stage and make them co-decision-makers in the development process. Define goals together and create trust, acceptance and commitment. In this way, you can motivate your employees to actively help shape the introduction of a worker guidance system. Progress can be experienced together and the results of actions can be evaluated.

![]()

Continuous involvement in selection and implementation

Involve your employees in all phases of your approach. For example, carry out user tests with selected colleagues before the purchase. This will quickly show how and where the worker guidance system provides the most support. Accompanying training courses on technical handling and training courses on structuring knowledge promote the exchange of experience.

![]()

Let the worker guidance system grow

Gradually open up new areas of application in your company. A worker guidance system can, for example, provide valuable support during the onboarding and induction of new employees. Even less experienced workers are immediately part of the team. They have access to all relevant information and can carry out work processes reliably. You should also allow sufficient time for feedback meetings. This allows you to optimize the system together with your workers and for your workers.

Conclusion

Whether in the automotive industry, process industry or logistics - worker guidance systems can be used wherever manual tasks dominate the working environment. The industry plays a subordinate role here.

Once you have found the right worker guidance system, it does not have to be limited to the initial application. Such a system can often be rolled out to other areas in your company. Get your employees on board at an early stage to create acceptance and find the best possible solution for everyone who works with the system.

Free e-paper: How do you find the right worker guidance system?

Are there manual activities in your company with potential for optimization? If so, a digital worker guidance system would be a wise investment to reduce costs and increase productivity. We explain how to find a suitable guidance system in our free e-paper. Get it now and secure your knowledge advantage.

Worker guidance with weasl

More efficiency in your production

Modern production poses a challenge to systems and workers.Increasing numbers of variants and decreasing numbers of pieces per order entail constantly changing work instructions.

Meet this challenge with the right system.weasl helps you master highly-variant production with maximum efficiency.