June 28, 2023 | Author: André Nimtz | Reading time: approx. 10 minutes

What is worker guidance?

Worker guidance is a system that provides workers in industrial manufacturing with instructions, information, and any visuals they need to complete a given step.

In principle, a worker guidance system can also be a paper-based work instruction system, but in the course of digitalization, the term has become established primarily for digital systems.

Digital worker guidance makes it possible to guide workers interactively step by step through their work assignment.

At each step, the worker receives the required information, can record data and provide feedback. Such a worker guidance system contributes directly to increasing efficiency, avoiding errors and ensuring quality.

This already shows that worker guidance can also do much more than simply instruct workers: In addition to being used in assembly, worker guidance systems can be used for quality assurance, material tracking, maintenance processes, and even training new employees.

Digital worker guidance is an essential part of modern manufacturing and can be used across roles and systems.

What types of worker guidance are there?

When we talk about worker guidance or worker guidance systems, we always have to distinguish which systems are available on the market. The selection is wide and not every system makes sense for every area of application.

Digital platforms for work instructions

Digital software platforms for work instructions are replacing what used to be Excel files or printed manuals. With such a platform, you can create work instructions, enrich them with the necessary parts list information and release them for processing. It gives you an intuitive representation of the work steps, reduces the risk of errors and can often be connected to existing systems such as ERP and MES. In addition, such a platform can also be used for communication between workers and managers.

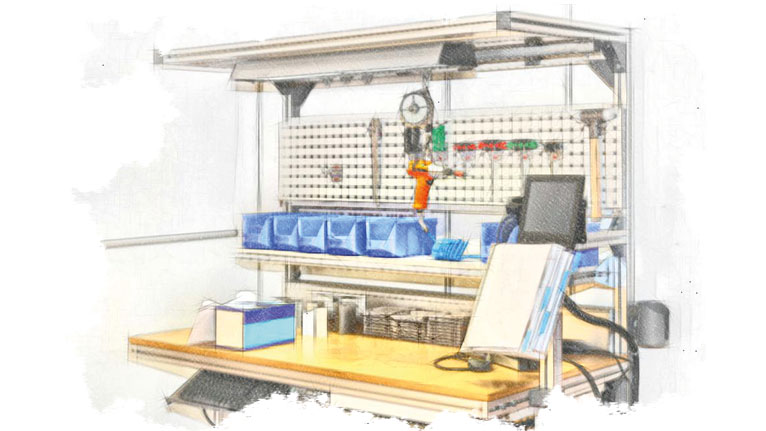

Workstation systems

These worker guidance systems are also based on software, but they also include a complete hardware workstation. The workstation is usually designed for specific production processes and consists of a monitor on which the required content is visualized, as well as an assembly table, shelves, storage bins, lighting, tool holders, etc. The workstation can also be equipped with a signaling system. Worker guidance can be precisely interlocked with the physical conditions here and connected, for example, with a signal generator for material selection.

Wearables

Wearable devices such as smartwatches, wristbands or smart gloves can also transmit instructions to the worker. In addition, you can use sensor technology to record data on work hours, movements or ambient conditions. In doing so, they can complement a software-based digital worker guidance system and simplify individual steps.

Augmented Reality

AR technology projects digital information onto the physical work environment in real time. With appropriate AR glasses, workers receive information on assembly steps, troubleshooting or quality checks directly in their field of vision.

This is only a selection of basic systems. In addition, there are many specialized forms of worker guidance. But one thing must be emphasized: The basis of all these systems is always a powerful software platform that provides all the functions for the specific worker guidance.

7 advantages of digital worker guidance

Reduce the workload of your employees

Probably the most important reason for digital worker guidance is the possibility to noticeably decrease the workload of your employees. Your workers no longer have to spend time gathering documents and interpreting instructions. You provide your employees with the necessary information for the respective work step digitally, according to qualification and without misunderstanding, so that your workers can fully concentrate on their value-adding activities.

Avoid errors, increase product quality

By using a worker guidance system to create work plans step by step and enrich them with information, you describe even complex issues precisely and unambiguously. This reduces the sources of errors, misinterpretations and minimizes ambiguities. If necessary, you can check the correct execution using a test step - an invaluable advantage of digital worker guidance compared to paper and Excel.

Consistent documentation

Worker guidance always brings along the possibility of documentation. In contrast to paper-based work management, however, digital systems enable automatic logging during work execution. Every digitally guided step is documented in the worker guidance system and its results are stored. You benefit from complete traceability of all orders. You can use the data obtained to identify bottlenecks or inefficient workflows and thus optimize processes and use resources more efficiently. For your workers, additional documentation efforts are eliminated, while at the same time data, results and measured values cannot be lost.

Transparency regarding the current status

Modern digital worker guidance systems can be used by different roles in your company together. Workers work with the same system as plan creators or schedulers. This enables maximum transparency about current order statuses.

For management, this means above all: you don't have to wait for paper- or Excel-based documents to be transferred.

Employee satisfaction through reliable processes and better communication

With a worker guidance system, you establish standardized processes that give your employees security and thus reduce their workload. In addition, modern systems enable bidirectional communication between shopfloor and topfloor. Employees can provide feedback at any time and enter into an exchange quickly and easily.

Simplify training processes

Thanks to a high degree of interactivity and all the necessary information, digital worker guidance software quickly and efficiently trains your employees for new processes. Visual support and knowledge-based process guidance accelerate the learning process, shorten training times and save employee resources. The result is faster training and thus more flexible workforce planning.

Mobility

A particular advantage of digital worker guidance as a software platform is the ability of workers to be mobile. Digital worker guidance systems follow modern layout and usability trends and can therefore be used barrier-free on large displays as well as on tablets, smartphones or specialized industrial hardware. For your workers, this means that they can work with one and the same solution on all end devices - without interruptions or synchronization problems.

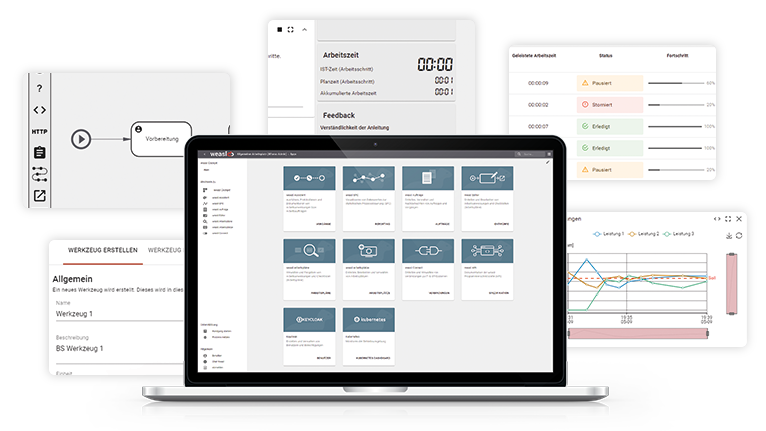

Why is a particularly flexible worker guidance system like weasl best for modern worker guidance?

Worker guidance with a digital system can help you and your company make significant progress. The prerequisite is that the worker guidance system fits perfectly to your needs and use cases. But is that even possible with standard software? Yes, it works perfectly, as long as this software is flexible enough to adapt to your circumstances. Our worker guidance system, weasl, provides everything you need.

By choosing weasl, you are relying on a particularly flexible system that:

- can map your processes as they really are. weasl can realize linear sequences as well as complex process paths and decision trees. This means that you are prepared for all conceivable process variants - today and in the future.

- can provide all the media you need. Often, images and text were not enough. Our system therefore also understands Excel, CAD and Co.

- can communicate with your existing systems. weasl comes with open interfaces to connect your systems or to be integrated into your systems.

- is flexibly expandable. Requirements change and your worker guidance system should be able to grow with new tasks - modularly or through individual apps. No worries as far as weasl is concerned.

- fits your operating model. Can you run a SaaS environment or should the system run on your servers? weasl understands both and allows you maximum flexibility in operation.

- is open for different application areas. A flexible software for worker guidance supports not only in assembly, but also in maintenance, quality assurance and other areas. It makes work easier for the worker as well as for the scheduler and the production manager.

Request product infos & get to know weasl

Conclusion

With a digital worker guidance system, you use a powerful tool in your production that helps you to reduce the workload of your workers, to ensure quality and to optimize processes. A worker guidance system enables your workers to concentrate on their value-adding activities and relieves them of significant effort in work preparation and documentation. At the end of the day, you save valuable time and resources and thus increase your competitiveness.

The right system for your needs: learn more about weasl

weasl reduces the workload of your employees and guides them through their work orders without errors. weasl makes it easier to train employees and supports you during training sessions. weasl documents all progress digitally and without additional effort. Experience true flexibility with weasl.

Do not miss any news: sign up for our newsletter

We regularly deliver news about our products and solutions directly to your inbox. Get exciting insights into customer projects and stay on top of IoT news and trends. Simply sign up for our free newsletter.