January 19, 2023 | Reading time: approx. 8 minutes | First published in MPDV News 2023.

From cooking tops to innovative high-tech materials, SCHOTT AG has proven expertise in the manufacturing of specialty glass and glass ceramics. To achieve consistently high product quality in these demanding processes and materials, the worker must execute the complex machining processes without error. The digital worker guidance system weasl from solution provider iSAX supports the worker in his or her work. The use case shown explains the benefits for the customer and the interaction of all integrated systems such as ERP, MES and worker assistance.

About SCHOTT

Pioneering - responsibly - together. These attributes characterize SCHOTT as a manufacturer of high-tech materials for special glass. Founder Otto Schott is regarded as its inventor and became the pioneer of an entire industry. To constantly open up new markets and applications with a pioneering spirit and passion - this is what has been driving the #glasslovers at SCHOTT for more than 130 years. Present in 34 countries, the company is a competent partner for high-tech industries. With the best teams, supported by the best digital tools, the group wants to continue to grow.

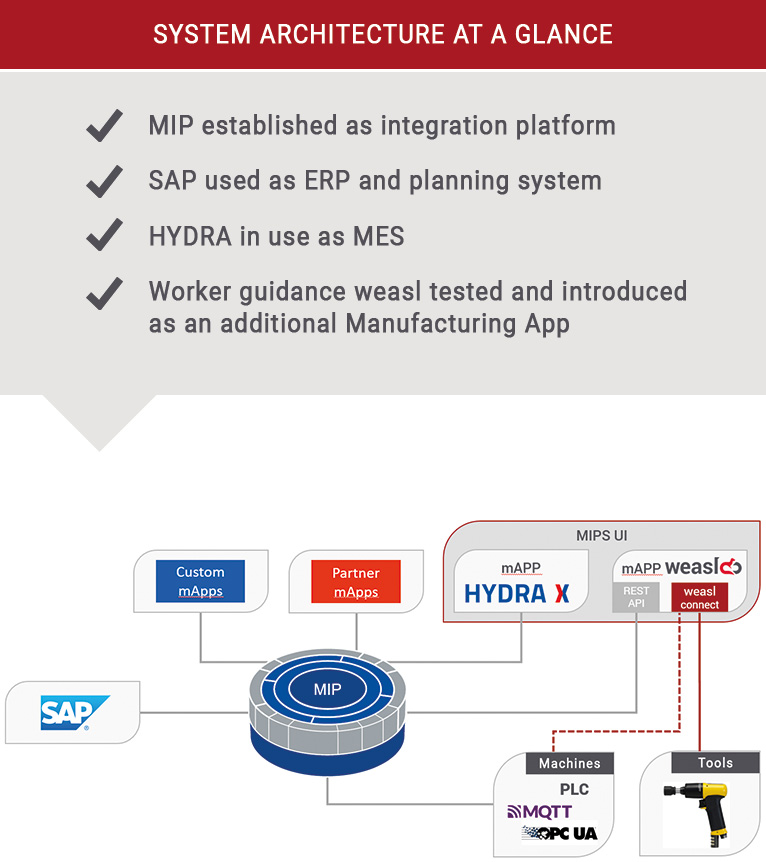

SCHOTT's digitalization strategy pushes for a long-term, sustainable and thus flexible solution architecture. To meet these requirements, the company decided early on to use the Manufacturing Integration Platform (MIP) as a basis. Existing applications are easily connected to it, and new applications are added in a time-saving manner - regardless of whether they are mApps from MPDV or third-party providers such as iSAX. On the one hand, this enables SCHOTT to always offer employees in production an integrated solution that optimally fits their needs. On the other hand, the overriding digitalization goals can be pursued.

"When selecting the worker guidance system, the main requirement was to find a standard solution that could be flexibly adapted and quickly and easily integrated," explains Heike Vocke, Managing Partner of iSAX GmbH & Co. KG. Other goals included going completely paperless in manufacturing and optimizing processes to ensure product quality: "With our weasl worker guidance system, we were able to meet all requirements." The software is used at SCHOTT as a manufacturing app in conjunction with the HYDRA manufacturing execution system (MES) based on the MIP integration platform. Since its introduction, weasl has helped to increase quality, productivity and efficiency in production and to reduce costs.

Reasons for a worker guidance system

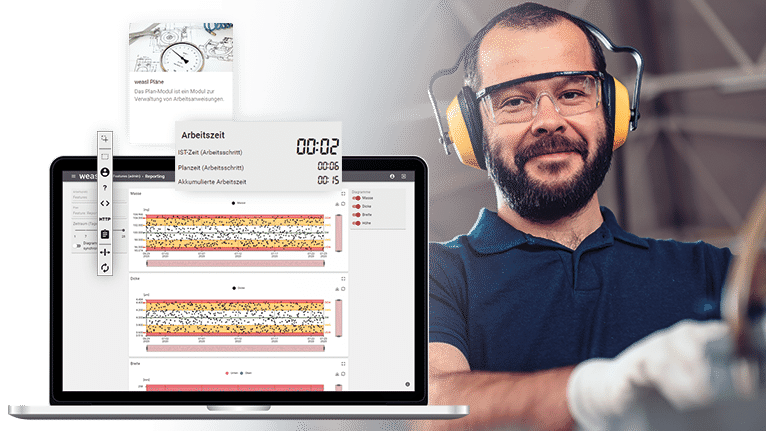

weasl optimally guides executing workers in their work and enables them to perform certain activities in a process-safe and error-free manner. This is particularly relevant when the variety or complexity of products increases. Thanks to a worker guidance system, process and product quality increases – especially with regard to quality repeatability. After all, the real objective is to avoid rework and scrap.

It is also a simple matter of documenting the information generated during the work process in a paperless manner and passing it on to other systems. For example, real-time data from manual activities can be linked to detailed production planning. This means that rescheduling can be triggered quickly if a machine breaks down or material is missing. A useful side effect is that the workload of the operator is reduced.

Stay up to date – subscribe to our newsletter now

We regularly deliver news about our products and solutions directly to your inbox. Get exciting insights into customer projects and stay on the cutting edge of IoT news and trends. Simply sign up for our free newsletter.

Help during CNC machining

End-to-end data integration provides the necessary overview: "SAP provides the production orders via the integration platform MIP. The detailed work plans and concrete work instructions are created in weasl's process editor, so that employees are later guided optimally, step by step," says Vocke. All data is transferred to the machines' shopfloor terminals for execution of the production order.

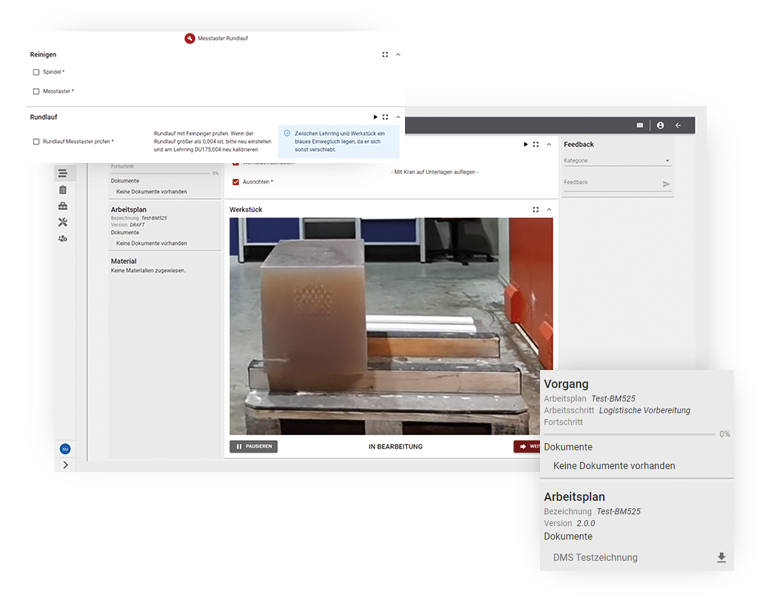

In the initial phase of the project at SCHOTT, it is primarily machine operators who are being supported in CNC machining: "The idea was to get rid of the Excel-based paper instructions and to enable direct feedback from the workers," explains Vocke and adds: "They now receive all the information they need to set up the machine at a glance - including instructions on what to pay particular attention to". Since CNC machining can take a long time, tests and measurements must be performed regularly during the operation. The worker enters the measured values directly at the machine terminal. All data is available centrally and it is possible to track exactly how a part was machined on a machine. Feedback of the machining order and all execution data is provided by weasl via the MIP to HYDRA or SAP.

System architecture at SCHOTT

The information on production orders, workstations and resources required for worker guidance is made available via the MIP integration platform. The associated step-by-step work instructions are provided by weasl.

All mApps can be integrated on a uniform user interface via the MIPS UI user interface, which was specially developed by SCHOTT. Thus, the worker always has all the information needed for his or her tasks available in an up-to-date manner for each work step. Both weasl and HYDRA's MES applications integrate into the MIPS UI. According to Vocke, it was particularly exciting to see how quickly manufacturing apps like weasl fit into the overall architecture. The integration of the worker guidance system via the MIP connector with HYDRA was challenging, "but the teams also managed to do a great job jointly," says Vocke happily.

weasl – the system that optimally supports your employees

Whether you want to train new employees or provide experienced colleagues with precise work instructions for new processes - weasl is a powerful tool that supports and relieves your employees.

We invite you to our on-demand webinar on worker guidance

Learn how to master typical challenges in manual production with a worker guidance system. Using practical examples, we will show you how modern systems work and how you can benefit directly from them.