April 17, 2023 | Author: Christin Senftleben | Reading time: approx. 6 minutes

How do we preserve our natural resources and protect our environment? How do we want to organize lifetime and work? Which responsibilities do we assume as a society and what do we pass on to our children? Sustainability deals with all these questions. It is one of the great concepts of our time.

Sustainability is closely linked to the digital transformation. The industrial Internet of Things makes it possible to break up old structures, rethink manufacturing processes, fully exploit potential and produce with the lowest possible use of resources.

In recent years, a wealth of tools has been developed that focuses on analyzing data and presenting usable information. They support those responsible on the top floor to make well-informed business decisions and establish sustainable processes in the factory. But what about support on the shopfloor?

Workers on the shop floor are and will remain an indispensable value-creation factor in manufacturing. However, they receive little support in performing their manual tasks. Yet this is precisely where one of the greatest potentials for sustainable action in the factory lies. With our worker guidance system weasl, every manufacturing company is now in a situation to leverage this valuable potential!

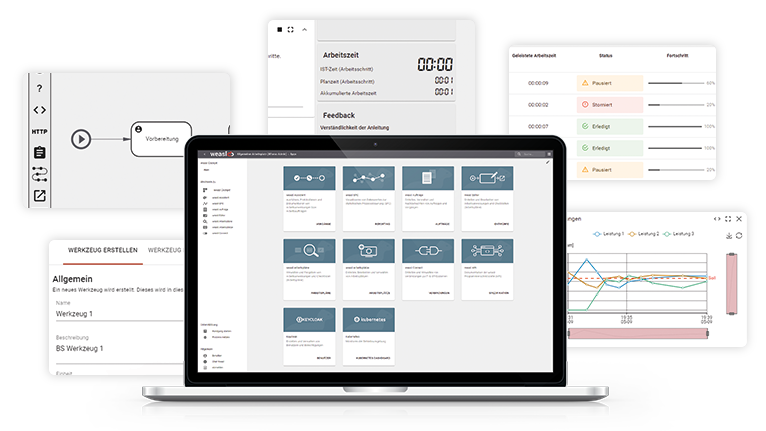

The strength of this worker guidance system lies in its unique flexibility, which makes it incomparable to other systems and particularly user-friendly. weasl creates the interface between people and the digital world. It supports a wide variety of use cases, integrates into any IT landscape and customer domain, is highly scalable and can thus be used in any size of company and industry.

Added values of weasl for sustainable production

We understand sustainability as a concept that combines the four dimensions of ecology, economy, social issues and technology. With weasl, companies achieve added value in all of these areas.

Ecological added values

What is the goal?

preservation of the company & protection of the environment

What is the task?

optimize resource utilization

What is the benefit for the user?

weasl supports manufacturing companies - especially in production, assembly and maintenance - in managing value streams. Through the intelligent networking of people, work equipment and processes, continuous tracking and tracing is possible. This in turn enables

- efficient use of all production resources

- a high level of transparency and thus decision-making capability on the shopfloor

- early error detection and the reduction of rework

This saves resources – in terms of raw materials and manpower.

What does weasl do?

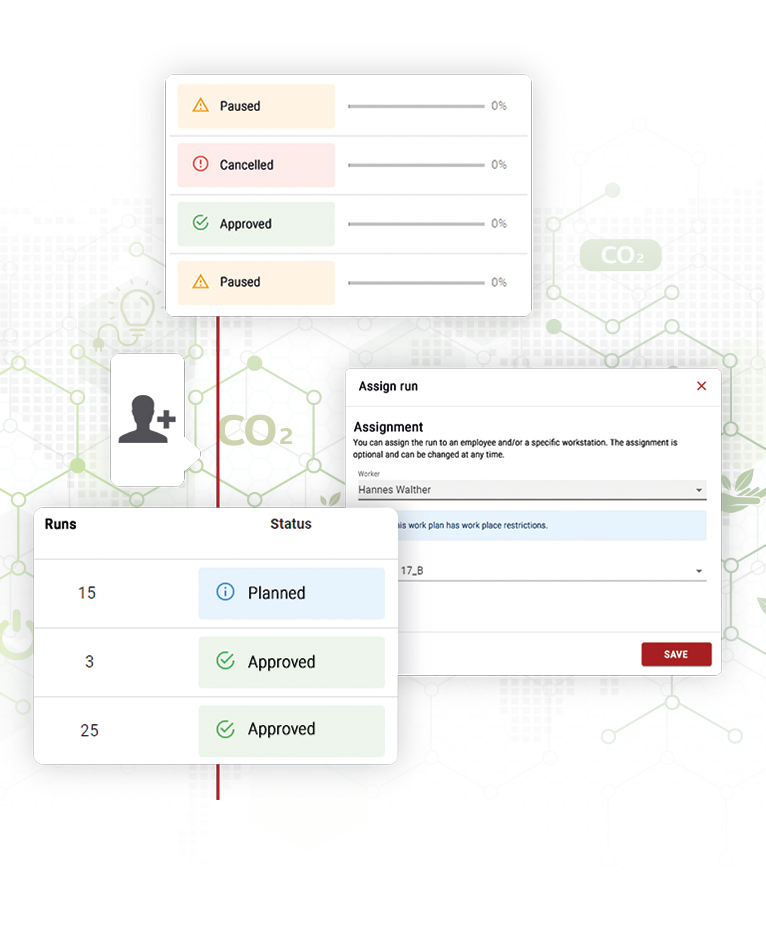

weasl collects data from manual and partially automated workstations during execution in real time. This increases the feedback quality and rate and eliminates media breaks between production systems and to the employees on the shopfloor. The manufacturing process is digitally documented throughout and is logged and audited in a time-saving method. Thanks to the integrated order control, the material planners or production managers have an up-to-date view of the production order progress. This allows them to react more quickly to changes.

What is the result?

- effectiveness and efficiency are increased

- resources are preserved

Economic added value

What is the goal?

long-term increase in efficiency through available knowledge

What is the task?

securing business-relevant knowledge for the future

How does the user benefit?

The shortage of skilled workers is increasing. Knowledge loss due to retirement or the "war for talents" is becoming a threat. At the same time, the increasing complexity in manufacturing demands more and more knowledge from the worker. "Knowledge" and the "experience of qualified key employees" must be sustainably secured in order to maintain the resilience and competitiveness of companies. weasl sustainably secures knowledge by

- easily and quickly establishing systematic and comprehensive knowledge management on the shopfloor

- capturing existing process knowledge digitally and making it available during the execution of the operation

- making the skills and activities on the store floor accessible and applicable to all employees

What does weasl provide?

Responsible persons create digital work plans and instructions directly in the plant management. Programming skills are not required. There are virtually no limits to the description of a sequence of work steps and the design of work instructions. The highly flexible process designer enables simple and fast modeling of workflows of any complexity using drag-and-drop. With the flexible work step designer, you describe the correct work execution and incorporate various media such as videos and CAD drawings.

What is the result?

- experience and knowledge are built up in the company in the long term

- tasks and problems can be solved efficiently

Social added value

What is the goal?

high employee satisfaction and increased motivation

What is the task?

involving employees and making changes manageable

How does the user benefit?

In modern, multi-variant manufacturing, workers must perform a wide variety of tasks safely and without error. Each process requires different knowledge and demands constant retraining of the worker. The smaller the batch sizes, the more the human factor becomes a potential source of errors. weasl helps manufacturing companies to

- strengthen the competencies of their employees on the shopfloor in the long term

- make complex processes controllable

- create a positive, supportive work environment that takes into account the individual qualification level of the employee.

This ensures a lower error rate and also more motivation among employees. As a result, efficiency, productivity and employee satisfaction are increased in equally high measure.

What does weasl provide?

weasl automatically provides the employee with user- and task-oriented information as well as clear and unambiguous work instructions. It guides them step by step through the work process. In this way, every employee receives the right information, at the right time, in the right place, and in the appropriate form. An integrated feedback function allows the employee to report when problems occur during the execution of work steps.

What is the result?

- shorter training and training periods

- uncertainties reduced & knowledge made available

- higher efficiency and productivity

Technological added value

What is the goal?

continuously optimize processes and remain competitive

What is the task?

improve technological and digital maturity

How does it benefit the user?

weasl integrates a wide variety of systems so that the company achieves greater transparency and control on the shopfloor and employees can concentrate on their core tasks. In the process

- weasl displays all information relevant to the worker in a clear and up-to-date manner

- weasl supports employees by relieving them of data entry and documentation tasks

- integrates weasl with (existing) business applications and AI algorithms

In this way, a consistent and sustainable solution architecture is systematically established, even in SMEs, and production processes are better integrated.

What does weasl provide?

With weasl, production-oriented work steps and digital work instructions are created without programming knowledge. The time and effort required to create work plans is reduced, as is the time and effort required to set up workstations and provide materials and resources. Thanks to the simple integration of the existing production and IT environment, employees are optimally guided in the event of deviations and disruptions in the sequence and current process data is taken into account in production planning. Technology specifications that cannot be implemented optimally are identified, communicated and eliminated more quickly. This approach enables continuous quality and process improvement.

What is the result?

Production processes and systems are integrated across the whole process

Conclusion

weasl has an impact on various levels of sustainability in the factory. With weasl, manufacturing companies save raw materials and the environment, increase their efficiency and create better working conditions for their employees on the shopfloor. They sustainably secure their competitiveness and position themselves as an appealing employer.

Experience weasl live

Get to know the features of weasl and find out what our system can do for your company. Write to us and we will get back to you as soon as possible.

Worker guidance with one of the leading systems: weasl at a glance

weasl creates the interface between people and the digital world. It supports a wide variety of use cases, integrates into any IT landscape and customer domain, is highly scalable and can thus be used in any size of company and industry.

Don't miss any news: Sign up for our newsletter an

We regularly deliver news about our products and solutions directly to your inbox. Get exciting insights into customer projects and stay up to date with IoT news and trends. Simply sign up for our free newsletter.