Definition: What is setup time?

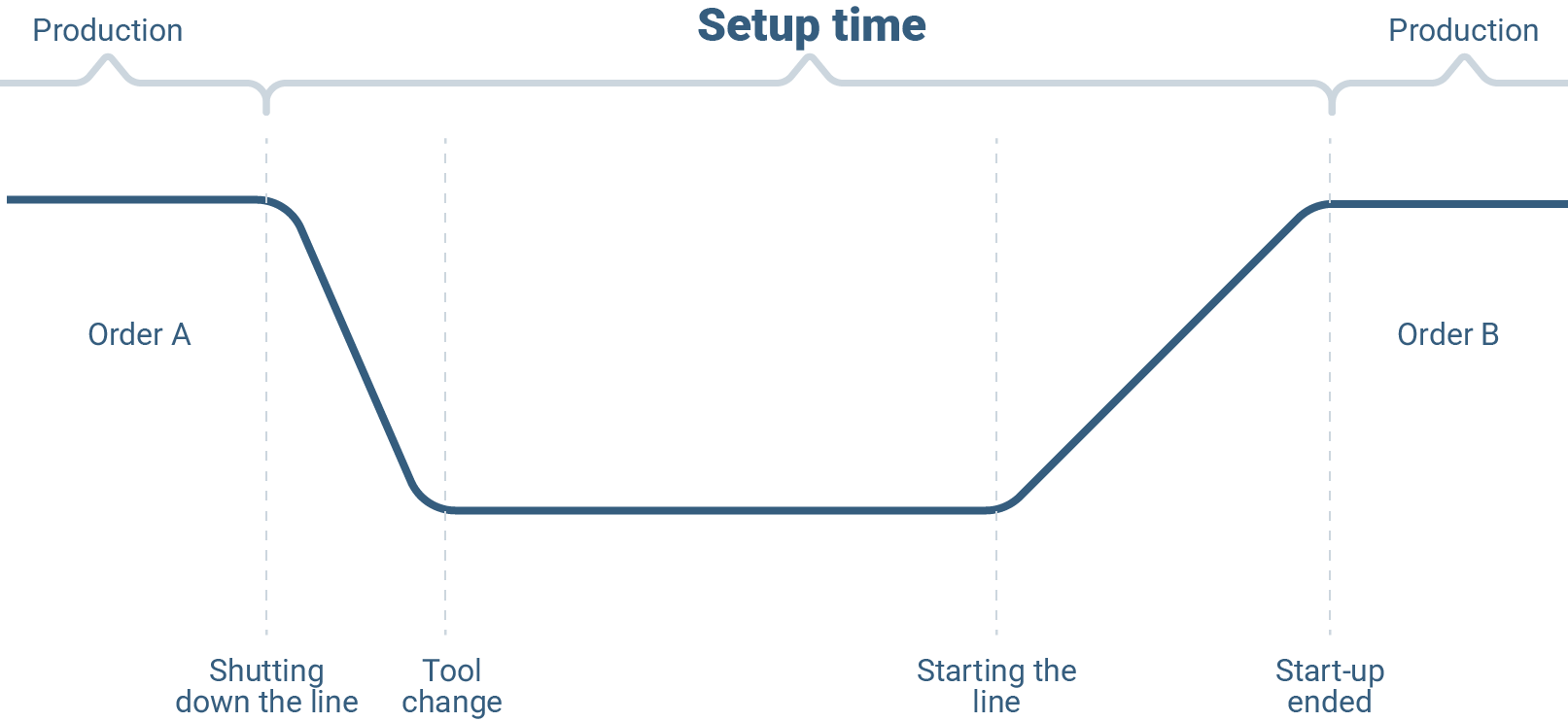

Setup time is the time required to prepare and return a work system - for example a machine, a system or a piece of equipment - before and after the order is executed.

REFA abbreviates the setup time with the time type tr. Together with the execution time ta, it results in the order time T.

Setup times are downtimes during which no added value is created. Accordingly, they have an effect on your productivity. The longer a machine or system has to be set up, the more value-adding working time you lose.

Summary:

- time for preparing and returning machines before/after an order

- part of the order time, but does not cause any direct added value

- long setup times reduce productivity due to machine downtime

Beispiele für Rüstzeiten

Während der Rüstzeit wird alles Nötige für einen Arbeitsauftrag vorbereitet – oder aber nachbereitet, um das Rüsten für den nächsten Auftrag zu ermöglichen. Die Maschine oder der Werker wird dadurch befähigt, ohne Umschweife oder weitere Vorbereitung wertschöpfend tätig zu werden.

Dazu wird zum Beispiel:

- ein Werkzeugwechsel in der Maschine durchgeführt

- die Anlage vor Produktionsstart auf Funktionstüchtigkeit geprüft

- eine Neueinstellung beziehungsweise Justierung von Maschinenparametern vorgenommen

- ein Montagearbeitsplatz vorbereitet oder aufgeräumt

Calculation of setup time

The setup time is made up of three components. Firstly, there is the basic setup time. This is the actual working time that an employee needs to set up a machine. Then there is the setup distribution time. This is reflected in a percentage time surcharge for unplanned interruptions such as tool searches or consultations. The third component is the setup recovery time - also a percentage time surcharge that takes into account the recovery phase after physically and mentally demanding setup work.

These three components result in a very simple calculation:

Setup time = basic setup time + setup distribution time + setup recovery time

Let's take a look at an example. Your employee needs 40 minutes to get a machine ready for operation. This is the basic time. In your experience, unplanned interruptions account for another 5 percent of the basic setup time, i.e. 2 minutes. Allow 10 percent, i.e. 4 minutes, for the setup recovery time.

This results in the following calculation: setup time = 40 minutes + 2 minutes + 4 minutes. Ultimately, the setup time for this one machine in our example is 46 minutes.

In order to be able to calculate those times adequately, you should record and evaluate the data of the setup processes. In this way, you can quickly calculate average values that are close to the actual setup times. This will ultimately save you valuable time.

Summary:

- setup time = basic setup time + setup distribution time + setup recovery time

- distribution and recovery times are added to the basic time as a percentage

- data acquisition of the setup processes helps to determine realistic average values and save time

Minimizing setup times as a goal

You can't do without setup times. The more varied production becomes, the more important it is to optimize setup times to the necessary minimum. The more efficient the setup process, the less downtime you have to record and the faster your employees can get on with their value-adding activities.

Minimizing setup times is the order of the day. And fortunately, there are already some tried-and-tested methods for doing so.

Single-Minute Exchange of Die (SMED)

Single-Minute Exchange of Die means something like “tool change in the single-digit minute range”. In general terms, this means that the changeover time from the last part of a batch to the first part of the next batch should be in the single-digit minute range.

To achieve this, internal and external setup processes are first separated. While the machine has to be at a standstill for internal processes, it can continue to run for external processes. Where possible, internal setup processes are transferred to external ones and both types of process are then optimized and standardized. The aim is to achieve setup times of minutes instead of hours.

Automation & modernization

A second way to minimize setup times is to modernize your technical framework. In many cases, certain setup processes can already be replaced by automated processes. Predefined machine programs can be processed independently by modern or modernized machines and thus support upstream or downstream setup processes.

There is also great potential in digitalization. Modern software solutions, from digital production planning to worker guidance systems, support your employees on the path to optimal setup processes.

Summary:

- reducing setup times increases efficiency in multi-variant production

- SMED separates internal from external setup processes and shortens changeover times

- automation and digitalization accelerate setup processes

Optimally support setup processes with weasl

Save your workers from confusion and time-consuming queries during setup processes. Provide them with meaningful digital work instructions that help them reach their goal quickly and without errors. Our worker assistance system weasl makes it possible.

Find out exactly how it works in our free showcase environment.