Definition: What is a process interlock?

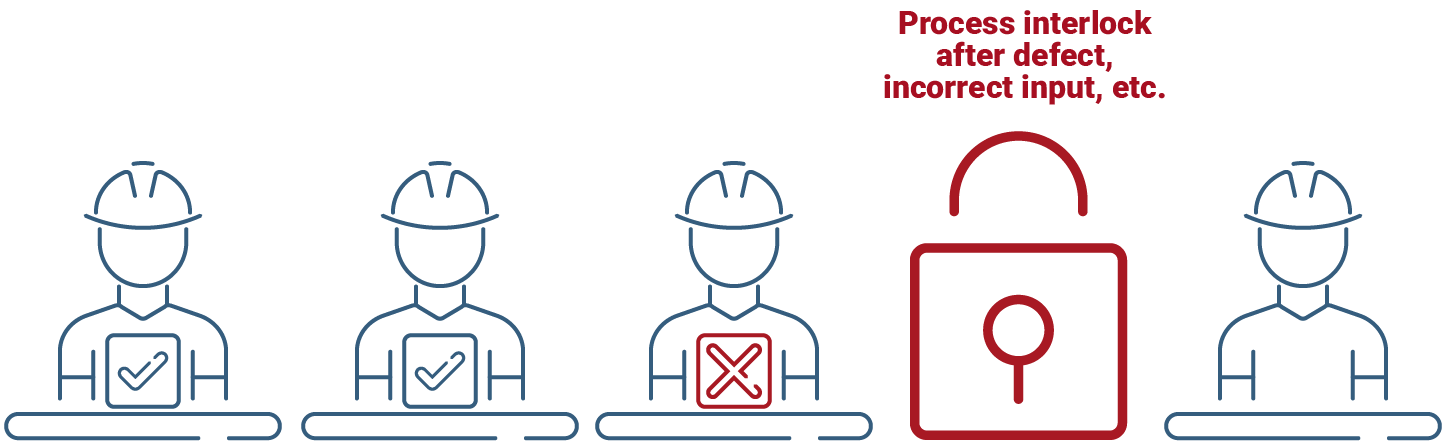

The term process interlock refers to safety and protective measures that can block or enable certain processes or states. This is linked to certain predefined conditions. If the conditions are met, a process step or a machine can be activated or continued. If they are not fulfilled, the process is blocked and the step or machine is stopped.

One such condition can result from continuous quality monitoring. If, for example, a sensor detects recurring quality defects, it can trigger a process interlock and prevent further bad parts.

The term process interlock originates from automation technology, where it is used in particular in process and control technology.

Summary:

- a process interlock blocks / allows processes depending on conditions

- serves safety and quality assurance

- term from automation and control technology

Requirements for a process interlock

Process interlocks can be used in both automated and manual production. However, it first requires a certain basic level of technology. This means that you need the appropriate systems and solutions to ensure that processes are actually interlocked if certain conditions are not met.

For a process interlock, it is not enough for your worker to recognize that a measured value is outside the tolerance range, for example. After all, without a control system, he still has the option of simply continuing.

However, the technological basis is only half the battle. It is crucial to define strict conditions for process interlocks.

To do this, you first define a process plan with the associated quality routes for all assemblies, parts, etc. in advance.

Next, set clear process parameters within clearly defined process windows. In other words, determine the tolerance ranges within which you can achieve optimum quality.

You also define criteria for checking and evaluating the processes.

You need all of this as a basis for the system-side decision as to whether a process needs to be blocked or not. If parameters are not adhered to, the system blocks further work and thus prevents errors in production.

Summary:

- process interlocks require a technological basis for automatic blocking

- manual decisions are not enough - the system must be able to intervene in a binding manner

- prerequisites: defined process plans, tolerance ranges and clear quality parameters

- in the event of deviations, the system automatically prevents the process from continuing

Advantages of process interlocks

In very general terms, you could say that a process interlock protects the process, the product and the employee. It enables early detection and therefore avoidance of errors - right from the start of the production process. Fewer errors mean fewer rejects and less rework. Process interlocks intervenes where quality-threatening errors and defects could occur.

A Process interlock not only benefits the product, but also your employees. It is part of clearly defined workflows and processes and helps to ensure that work steps are carried out in the correct sequence. It also brings clear guidelines and automatic checking mechanisms into everyday production, which your employees can rely on when carrying out their tasks. This leads to a noticeable mental relief.

And let's turn briefly to possible hazardous situations in the production process. Here too, process interlocks can provide valuable services by specifying preventive measures and structured processes that serve to avoid hazardous situations.

Summary:

- fewer errors: early detection prevents rejects and reworking

- more safety: clearly defined processes protect the product and employees

- simpler work: Specifications and inspection mechanisms take the strain off your employees

Examples of process interlocks in production

What could a process interlock look like in specific production scenarios?

Example #1: material withdrawal

Let's disregard the numerous necessary parameters and assume that we are dealing with material withdrawal in the production process. A specific material must be provided for the next work step. If you do not use a process interlock and your worker picks the wrong material, this will result in bad parts or at least costly reworking.

Alternatively, your worker can enter the material number in their worker guidance system using a scanner, for example. The system then checks the number. If the material number is incorrect, further process steps are blocked. The worker cannot continue with their work. Only when the material number matches the specifications can the process continue.

Example #2: quality control after pre-assembly

In this scenario, the assembly of the component has already been completed and quality control is being carried out. You have defined the corresponding values as quality criteria for the process interlock - for example, as test steps in the digital work instruction provided by a worker guidance system.

The worker or quality controller now carries out the corresponding tests and enters the measured values. If they do not meet the predefined quality criteria, the component is returned for reworking. If everything fits, the next work step can follow.

Summary:

- material inspection: incorrect material is detected by scans > the process stops

- quality control: deviating test values lead to rejection and prompt error correction

- process interlocks ensure compliance with specified processes and quality standards

What is the goal of a process interlock?

A process interlock is a “tool” in your production that is designed to ensure that processes run safely and correctly. It can become an important milestone on your way to zero-defect production.

Create processes that enable your workers to work safely

Guide your employees through their assignments with clear guidelines and ensure that no mistakes can creep in. How do you do that? With digital work instructions in our worker guidance system weasl.

Experience it for yourself - in our free showcase environment.