Definition: What is manual assembly?

Manual assembly is a production method in which only employees and tools are used. The focus here is on people, who carry out the individual work steps by hand using suitable tools. This work includes, for example, measuring, sawing, drilling, grinding and general assembly.

There is no degree of automation in manual assembly. However, this does not mean that the worker cannot be supported by appropriately optimized workstations or digital tools. In order to optimize the work processes and minimize the error rate, the employee is supported by, for example

- ergonomic workstations

- computer-aided systems

- smart tools

- precise measuring instruments

Summary:

- All work steps are carried out by hand - without automation.

- Typical tasks include measuring, sawing, drilling, sanding and assembly.

- Ergonomic workstations and smart tools support the process.

How does manual assembly work?

Manual assembly essentially consists of four phases: preparation, execution, quality control and completion.

Phase 1: Preparation

The worker gathers all the necessary materials and tools and prepares drawings and work instructions or searches for them in the documents. Setting up the workplace is also part of the preparation phase.

Phase 2: Execution

In this phase, the employee first prepares all the materials. They measure material, cut it to size and shape and process components according to specified procedures. The components are then assembled and the surfaces finished if necessary - for example by painting.

Phase 3: Quality control

The worker carries out visual and functional checks and re-measures the relevant parameters. If he finds any deviations, the workpiece is sent for reworking.

Phase 4: Completion

The worker carries out any necessary finishing work and finally a final inspection. He documents the work steps and hands the product over to the customer or the next production stage.

Summary:

- preparation: prepare workplace, materials and tools, inspect documents

- implementation: prepare materials, process and assemble components

- quality control: visual and functional inspection, measurement, rework if necessary

- completion: finishing work, final inspection, documentation and handover

Advantages of manual assembly

In today's production world, manual assembly seems a little out of date. Nevertheless, it can bring advantages for certain areas of your production. Manual assembly enables

- more flexible personnel planning

- a faster response to customization requests

- the creation of new, specialized jobs

- the guarantee and assurance of high quality craftsmanship

- production with less investment

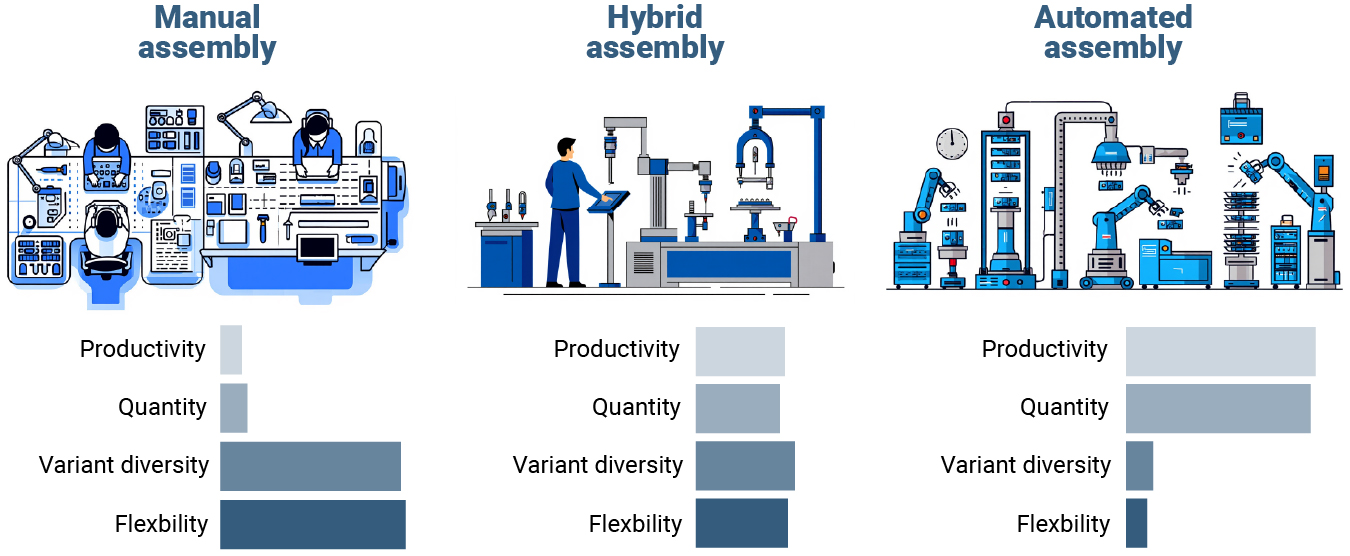

Hybrid & automated assembly

Let's assign percentage values for the automation of the production methods. Manual assembly is at 0% automation.

The next level is hybrid assembly - in other words, 50% automated assembly across the board. (Please note: we use the term “generalized” on purpose, as semi-automated can actually mean anything from 1 to 99%). In hybrid assembly, the process flow is not yet fully autonomous. Your workers are only partially supported by the automation technology, which does not completely relieve them.

The highest level of expansion is therefore 100% automated assembly. Here, robots, machines and computer control systems interlock seamlessly and work properly without human involvement or intervention. Humans no longer perform any production tasks, but still take care of upstream or downstream issues such as repairs, product removal or maintenance tasks.

Summary:

- hybrid: Man and machine work together; degree of automation from 1 - 99 %

- fully automated: Production is fully automated and computer-controlled

- humans are responsible for commissioning, monitoring and maintenance in fully automated processes

The optimal support for manual assembly

Manual assembly does not mean doing without digital support. Digital work instructions guide your workers optimally through manual assembly, facilitate quality controls and directly document all progress. You will find the ideal system for this in our weasl worker guidance system.

Experience it for yourself - in our free showcase environment.