Definition: What is Andon?

Andon is a visual or acoustic system used for the immediate indication of faults and problems in production. As a method of lean management, it has developed into a central tool for process monitoring and control.

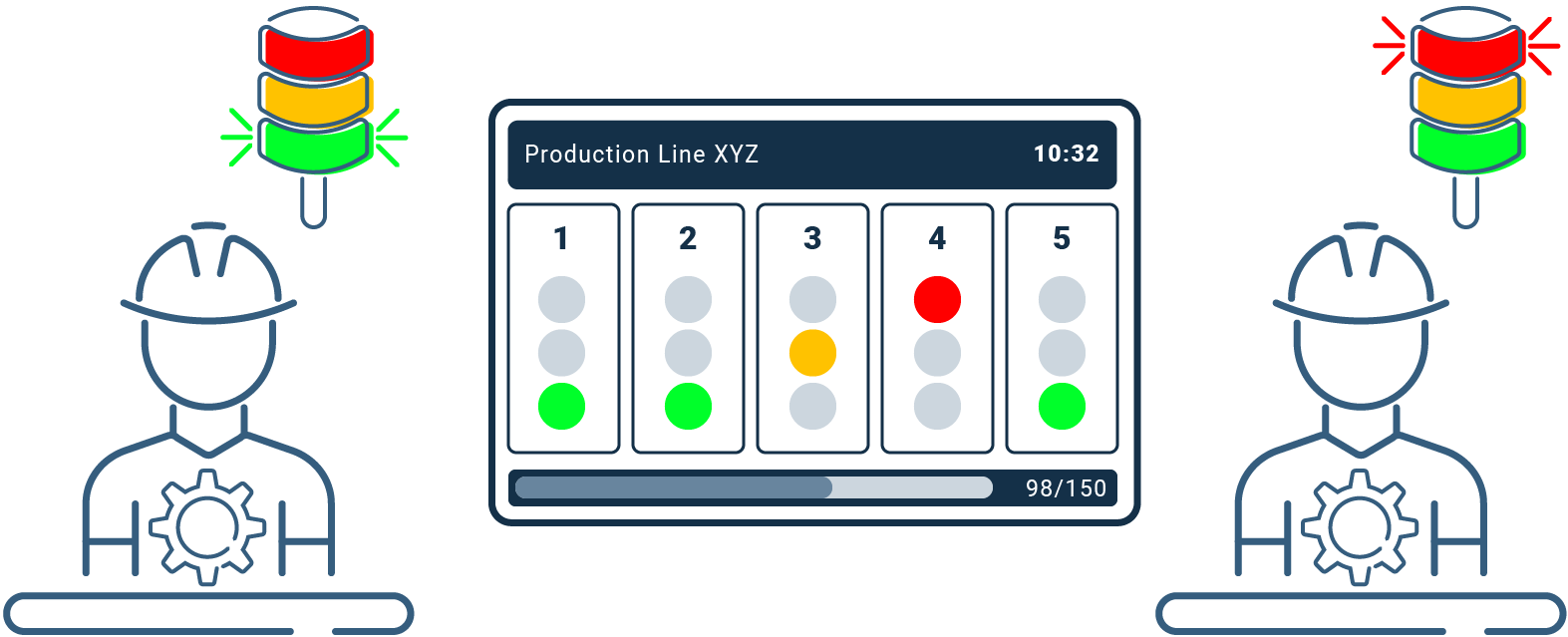

The term originally comes from the Japanese and refers to a traditional paper lantern made of wood and shoji paper. In today's production landscape, andon is probably most commonly found in signal towers with a traffic light system.

A more detailed and precise system can be found in the form of the andon board. Lean founder Taiichi Ohno already described such a board in the book “Toyota Production System” from 1978: "When one looks up, the andon (the line stop indication board) comes into view, showing the location and nature of trouble situations at a glance."

Summary:

- Andon system: visual and acoustic error message system

- modern application: Traffic light system for production status

- Andon boards show the source of the problem and the type of fault

Advantages of Andon

In very simple terms, Andon is an alarm system. Accordingly, the most obvious advantages result from the availability of such alarms:

- Employees and staff are informed immediately of any disruptions in the production process.

- An immediate alarm enables an immediate response and rapid problem solving.

- This speed advantage in turn increases productivity and quality.

- Continuous fault display and rectification promotes continuous improvement processes in your production.

- Fast fault detection protects your employees.

Summary:

- immediate alarms provide immediate information about faults

- high responsiveness enables rapid troubleshooting

- fault display indirectly promotes productivity and safety

How does an Andon system work?

To talk about how it works, we first need to distinguish which Andon system we are talking about: a basic alarm system, signal towers or a detailed Andon board.

Alarm systems

Alarm systems are - as the name suggests - designed to trigger an alarm. This is done, for example, by an Andon Cord - a pull cord or “ripcord” - which the production employee can activate directly on the system. Another variant is the Andon button - technically a different principle but the same function. The production system itself can also have functions that make automatic alerting possible.

Signal tower

A signal tower is used to display the production status or operating status at the respective workstation. The color signals are certainly familiar to everyone from everyday life: A green signal means that everything is OK. Yellow signals a warning or a potential fault that requires attention. If the signal column lights up red, a problem has occurred that is paralyzing production and must be rectified immediately.

Andon Board

An andon board is a dashboard that is usually displayed on a large central monitor in the production hall. It displays the current status of production lines, workstations or processes - like the signal tower in the colors green, yellow and red or also supported by acoustic signals (coded tones, voice messages, etc.). A modern Andon Board can be connected to surrounding systems such as ERP or MES and thus also display additional data. It creates transparency for all employees.

Summary:

- alarm systems trigger fault messages via pull cord or button

- signal towers display the production status using traffic light colors

- Andon boards visualize production and fault data

- modern systems are networked and create transparency for everyone

Risks from Andon

Imagine the place is literally on fire and signals and warnings are triggered at a wide variety of workstations and machines. The amount of alarms visible to everyone can quickly overload your employees and lead to significantly inefficient production processes.

The ability to react can also be impaired by excessive alarms. In the worst case scenario, your employees are repeatedly distracted from important tasks. This can lead to carelessness and errors.

It is also important that your Andon system is ideally set up and that alarms are really only triggered when there are problems. If there are too many false or unnecessary alarms, this reduces your employees' confidence in the system and may result in real problems no longer receiving sufficient attention.

Summary:

- Too many alarms can overwhelm employees and disrupt processes.

- Constant distraction reduces concentration and increases errors.

- False alarms undermine trust in the system.

Goals of Andon systems

With an Andon system, you create clear processes for dealing with warnings, problems and faults. Among other things, the aim is to

Visualize the operating status of machines, workstations or production lines and enable continuous monitoring

to consistently report irregularities so that immediate remedial action can be taken as part of a defined procedure

to stop production systems in the event of acute problems in order to defuse dangerous situations and prevent products of inadequate quality from being passed on to the next processing step.

Summary:

- visualization of the operating status for continuous monitoring

- reporting of irregularities for rapid rectification

- system stop in the event of acute faults to avoid hazards and quality defects

Easily record faults in the production process – with weasl

What does your worker have to do if he wants to record a fault in the middle of the production process? Very simple: press the button in weasl and report the fault directly in the system where he is working anyway.

Sounds good? Then take a look at the system - with our free showcase environment.