Definition: What is serial production?

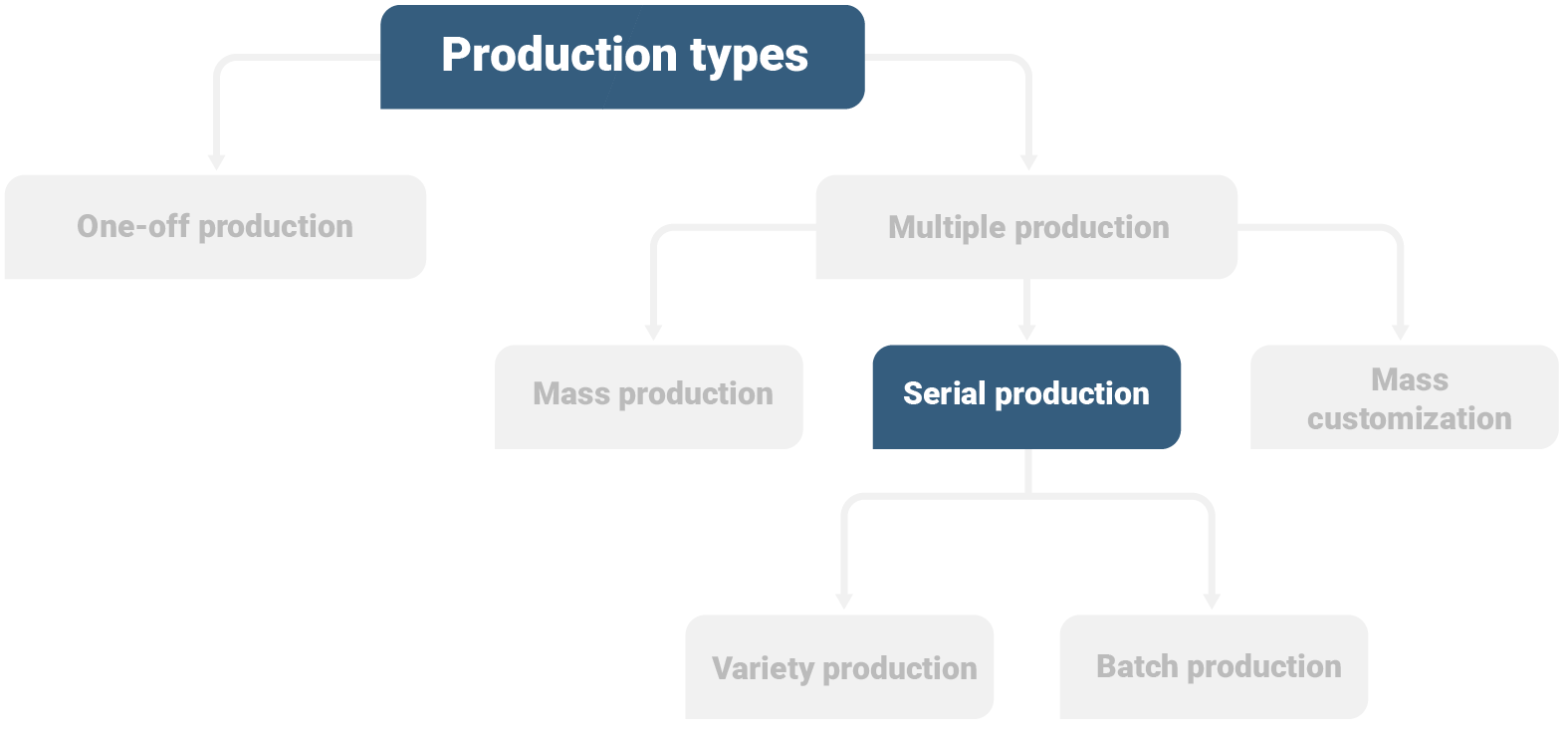

Serial production is a manufacturing process in which several similar products are produced simultaneously or in immediate succession. It is therefore an intermediate stage between one-off production and mass production.

In contrast to mass production, which is in principle unlimited, production in serial production is limited to a certain number of units greater than one. Serial production is therefore the manufacturing process of choice, especially when demand is lower or batch sizes are smaller.

Summary:

- production of several similar products in limited quantities

- intermediate form between individual production and mass production

- suitable for smaller demand or limited batch sizes

Advantages of serial production

Serial production has a number of advantages over other manufacturing processes. However, as already mentioned, it must fit the production goal. As you are not only producing individual items, serial production allows you to achieve significantly higher productivity at lower costs. And the cost aspect in particular has a positive effect on your production in many respects:

- You can manufacture similar products in series much more cost-efficiently.

- Larger production quantities per series reduce unit costs.

- More series means less retooling and this reduces your fixed costs in the long term.

Beyond this, serial production offers a good starting point for automating your production processes and opens up the possibility of just-in-time delivery. This in turn helps to optimize your stock levels and storage costs.

Summary:

- cost efficiency thanks to lower unit costs and reduced set-up time

- higher productivity thanks to repeated processes and larger batch sizes

- automation and just-in-time delivery possible

Disadvantages of serial production

Of course, serial production can also have disadvantages. For example, not every series can be sensibly reproduced using serial production. Small series in particular can lead to disproportionate costs.

If you manufacture in series, you restrict your production facilities to certain products, variants or models. This limits your production flexibility.

If you are not working on a specific order but on forecast demand, serial production carries the risk of overproduction. If you misjudge demand or it changes unexpectedly, in the worst case scenario you will be left with too many products.

Summary:

- high costs for small series can be economically inefficient

- limited flexibility due to specialized systems and fixed variants

- risk of overproduction if demand is incorrectly estimated

When does serial production make sense?

Let's assume that your company's business model does not include serial production for other companies. When should you switch to serial production then? It makes sense if

- your customers demand small quantities of a product.

- there are many repeat orders for the same product, resulting in a high degree of repetition.

- you want to meet seasonal demand, produce larger quantities of a product in certain periods and then switch back to other products.

What subtypes of serial production are there?

One-off production is always one-off production. But serial production is different. There are subtypes with different characteristics.

1. Variety production

In variety production, the products differ only slightly and by individual characteristics - for example, shape, size or color. The basic principle here is that the manufacturing process remains largely identical and is only adapted to the slight product variance.

You can find an example of varietal production in your local fashion store. The garments are basically the same, but are offered in different sizes.

2. Batch production

In batch production, differences arise from the manufacturing process and from batch to batch. Within a batch, the products should be identical, but involuntary deviations can still occur - for example in color, fragrance intensity, consistency or firmness.

Anyone who has ever bought tiles in a DIY store knows how important it is to buy packages from the same batch. This is the only way to rule out color variations. Another example is soap production. Here, one batch with consistent properties is produced per mixing container.

3. Special form of batch production

In a special form of batch production, differences in the result are not caused by the process, but by the raw material used. No matter how much attention you pay to absolutely uniform production and processing methods, the final product will still vary - for example in aroma or acidity.

You can find an example in your coffee cup. Even if the beans are always processed in the same way, the taste can vary because they come from different growing regions or vintages.

Summary:

- variety production: products differ only slightly (color, size, etc.)

- batch production: products from one batch are the same, but may differ from other batches

- special form: differences arise due to fluctuations in raw materials

The ideal support for your serial production

Setting up machines, carrying out quality checks, instructing employees in serial production - this works best with digital support. Our worker guidance system weasl provides the ideal toolset for this.

Experience it for yourself in our free showcase environment.