Definition: What is meant by processing lead time?

The processing lead time is a key performance indicator (KPI) in production and describes the time span from the start of production of a product to its completion. It therefore includes phases such as assembly, quality assurance and intermediate storage of the product.

The processing lead time is a time type developed and defined by REFA - the Association for Work Design, Business Organization and Corporate Development. It is identified as TD and has established itself as an important key figure for optimizing and monitoring the efficiency of processes.

How to shorten the processing lead time

So far, so simple. Precisely because the processing lead time covers the entire manufacturing time of a product, there are numerous starting points for shortening the processing lead time and thus optimizing production.

Process optimization

Take a close look at your processes and look for bottlenecks and non-value-adding activities. If you eliminate these, you will shorten your processing lead times.

Automation

In many companies, certain production processes can be automated. The costs incurred for this are recouped through shorter processing lead times and higher output.

Lean manufacturing

If you follow the lean manufacturing approach, you have set yourself the goal of eliminating waste, streamlining processes and optimizing material flows. All of this has a positive effect on your processing lead time.

Modernization

It also works at the technical level: invest in faster machines and innovative technologies in a targeted manner and speed up your production.

Training your employees

Don't forget your employees. Optimally trained colleagues know their tasks inside out and work particularly time-efficiently.

Continuous improvement processes

As part of continuous improvement processes, you always keep an eye on optimization potential in your production. This can also benefit processing lead times.

Summary:

- optimize processes and eliminate bottlenecks for greater efficiency

- automate and technically modernize for accelerated processes

- apply lean manufacturing for lean, low-waste processes

- train employees and use CIP

Advantages of short processing lead times

The advantages of shorter processing lead times are already apparent in the reduction options from the last chapter. Let's get back to the point:

- Short lead times mean that you produce faster and arrive at the finished product more quickly.

- Shorter processing lead times allow you to reduce your production costs, for example in the form of your warehousing costs.

- Last but not least, faster production is noticeable for your customers: faster delivery = satisfied customer.

The components of processing lead time

The lead time is made up of various individual time components. These include

Setup time

This is the time in which a machine is set up or converted for production and equipped with all the necessary machine parameters.

Transport time

This includes all the time required to transport the product from one location to the next - manually, by assembly line or by AGV.

Idle time

If the product cannot be further processed, idle time is incurred. This can be the case, for example, if the next work station is still occupied.

Storage time

Storage time is the time that the product spends in the warehouse - for example, until it is dispatched to the service provider who takes over further processing.

Processing time

This includes the pure processing times - i.e. the times during which production actually takes place.

Other times

Not everything always goes according to plan. Production times are also incurred for all unscheduled activities, which are part of the processing lead time.

Summary:

- production-related times: Set-up time, processing time and unplanned times

- logistics-related times: Transportation, storage and idle times

- Important: Each component offers opportunities to shorten processing lead times.

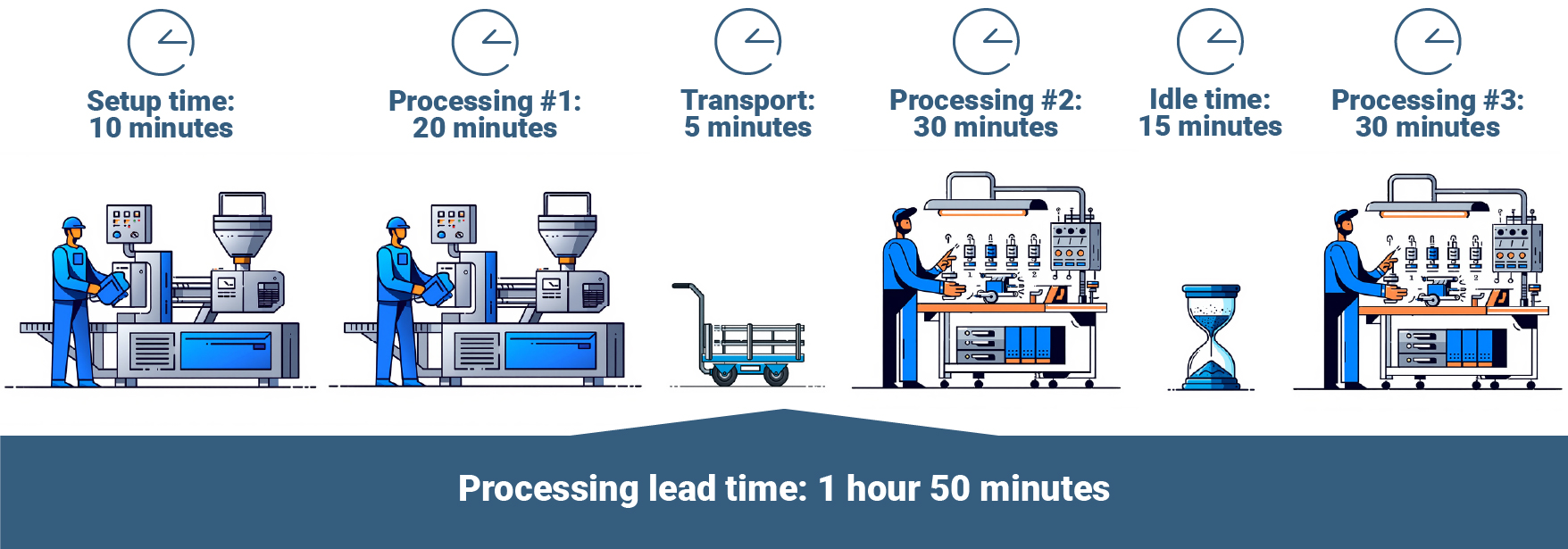

Sample calculation

The total processing lead time can be calculated from the individual components. The formula is very simple: you add up the individual time components of the entire production process as they actually occur.

Let's assume that in our production example we have a set-up time, several processing steps as well as a transport time and a waiting time. The formula could look like this:

Processing lead time = set-up time + processing time + transport time + processing time + idle time + processing time

Backed up with figures, this results in the following calculation:

| Machine setup time: | 10 minutes |

| Processing time 1 (injection molding): | 20 minutes |

| Transport to the next workstation: | 5 minutes |

| Processing time 2 (pre-assembly): | 30 minutes |

| Idle time until next assembly step: | 15 minutes |

| Processing time 3 (final assembly): | 30 minutes |

| Processing lead time: | 1 hours 50 minutes |

Shorter processing lead times with optimal digital processes

An effective digital solution for your production and assembly? Optimally trained and managed employees? Transparent, optimized processes? That sounds like a case for weasl. Our worker guidance system can provide you with sustainable support in key aspects of your daily production.

You can find out exactly what this looks like in our free showcase environment.