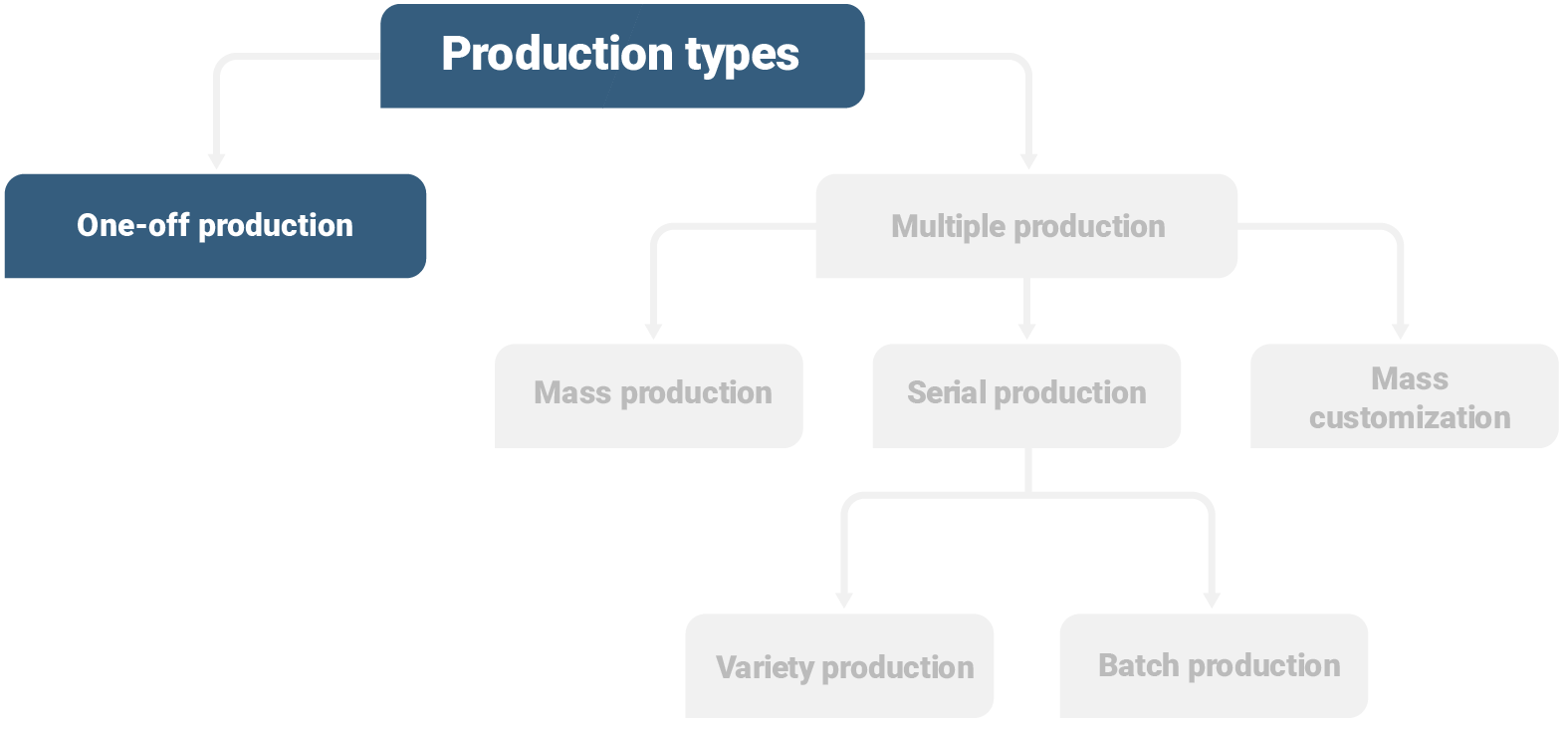

Definition: What is one-off production?

One-off production is a manufacturing process in which products are manufactured as individual items. It is therefore manufactured in batch size 1, even if the individual product is a prototype that is later to be mass-produced.

The production of individual parts is usually carried out manually and is associated with higher costs. One-off production is more complex and usually requires the corresponding expertise. In return, however, it offers the possibility of tailoring products to the individual requirements and needs of the customer.

Examples of one-off production

In principle, one-off production can be found wherever something is manufactured as a single piece. Your new fitted kitchen? One-off production. Your new tailor-made suit for the next event? Likewise. The bridge you drive over to work every morning? You guessed it: one-off production.

There are numerous other examples in industry:

- customized machines and special systems

- prototype construction

- customer-specific custom-made products

- large-scale projects such as ships, aircraft or power plants

Advantages of one-off production

Compared to mass production, one-off production is a very focused process that has a number of advantages:

- Flexibility: by working intensively on a single product, a high degree of flexibility is possible when making adjustments while the product is still being manufactured.

- Individuality: The product is manufactured exactly according to the customer's specifications and therefore has a high degree of individuality.

- Customer satisfaction: If you manufacture customized individual parts, the chances are high that your customers will be highly satisfied with the result and remain loyal to you in the long term.

- Quality assurance: Each individually manufactured product is also individually tested - in the best case down to the last detail. The result: maximum quality.

- Competitive advantages: When you manufacture unique products, you also gather a lot of expert knowledge that sets you apart from the competition.

- Sustainability: You only produce what is really needed. This helps you avoid waste and overproduction.

Summary:

- high flexibility and customization including adjustments during the process

- high quality, customer satisfaction and long-term customer loyalty

- competitive advantage and sustainability through expert knowledge and avoidance of waste

Disadvantages of one-off production

Of course, one-off production also has disadvantages compared to mass production. Firstly, there are the costs: the production of one-offs is more expensive - calculated per individual part - than serial production. Added to this is the time required. Processes usually have to be planned more elaborately in order to ensure that deadlines are met. In addition, your employees must also have specialist knowledge in order to master complex production processes safely.

Summary:

- higher costs per unit

- complex planning and longer production time

- increased need for specialist knowledge

The optimal support for one-off production

From the required specialist knowledge in the form of digital work instructions to sound quality control directly in the production process: weasl is your first port of call for efficient processes in one-off production and beyond.

You can experience what weasl can do in our free showcase environment.